Oripan Factory System is an system for production management, supervision and integration of the entire company structure. The aim of OFS is to innovate the production processes of each company, always having information and indicators available within a fully integrated system. OFS includes all production departments to improve efficiency, contain and manage costs, optimize maintenance and maximize the yield of plants and raw materials.

Making it better

With our exclusive focus on the bakery and pastry industry, we master every aspect of the production process. Understanding daily challenges from ingredient handling to final product quality, we develop integrated solutions that enhance efficiency, consistency, and performance.

Quality controls

In the modern bakery industry, digitalized and automated quality control is essential for ensuring consistency, efficiency, and traceability throughout production. Manual inspections are prone to…

Dosing and Mixing

Dosing and mixing are critical steps in the bakery industry, directly impacting dough consistency, texture, and overall product quality. Achieving precise ingredient dosing and optimal mixing…

Packaging & Order delivery

Packaging and delivery in the bakery industry present critical challenges that impact product freshness, efficiency, and traceability. Inconsistent packaging, labeling errors, and inefficient logistics can lead to…

Production line

One of the biggest challenges in the bakery industry is breaking the information barrier between management and the production floor. Manual data collection and siloed information prevent full visibility…

Raw material management

Effective raw material management is crucial in the bakery industry to ensure consistency, cost control, and traceability. Manual tracking of ingredient stocks, inaccurate inventory records…

Quality controls

In the modern bakery industry, digitalized and automated quality control is essential for ensuring consistency, efficiency, and traceability throughout production. Manual inspections are prone to…

Dosing and Mixing

Dosing and mixing are critical steps in the bakery industry, directly impacting dough consistency, texture, and overall product quality. Achieving precise ingredient dosing and optimal mixing…

Packaging & Order delivery

Packaging and delivery in the bakery industry present critical challenges that impact product freshness, efficiency, and traceability. Inconsistent packaging, labeling errors, and inefficient logistics can lead to…

Production line

One of the biggest challenges in the bakery industry is breaking the information barrier between management and the production floor. Manual data collection and siloed information prevent full visibility…

Raw material management

Effective raw material management is crucial in the bakery industry to ensure consistency, cost control, and traceability. Manual tracking of ingredient stocks, inaccurate inventory records…

A scalable, modular system:

grow at your pace

Designed for flexibility, our fully modular system adapts to your needs, allowing seamless expansion and upgrades as your bakery evolves.

- All

- Management

- Production

- Analysis

Management

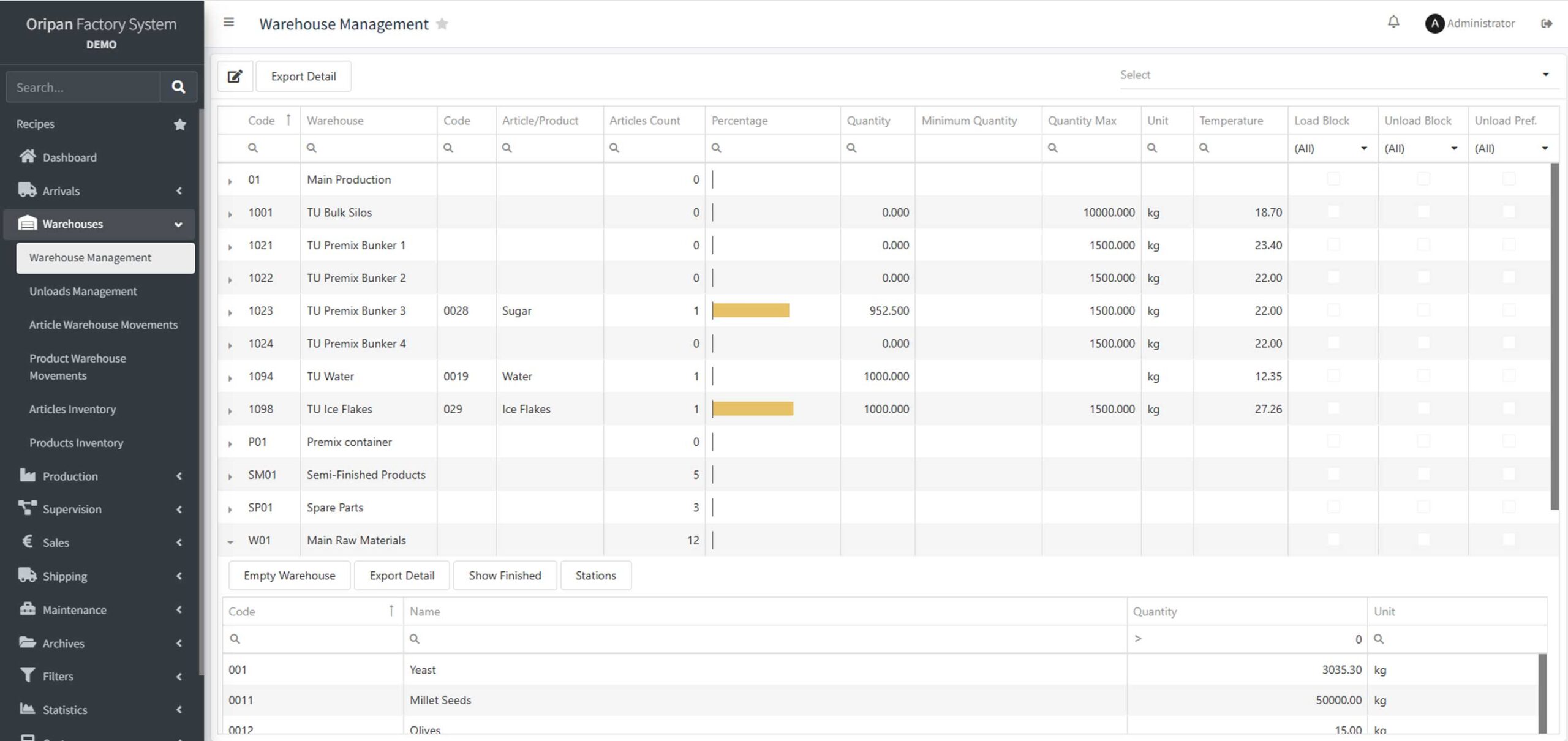

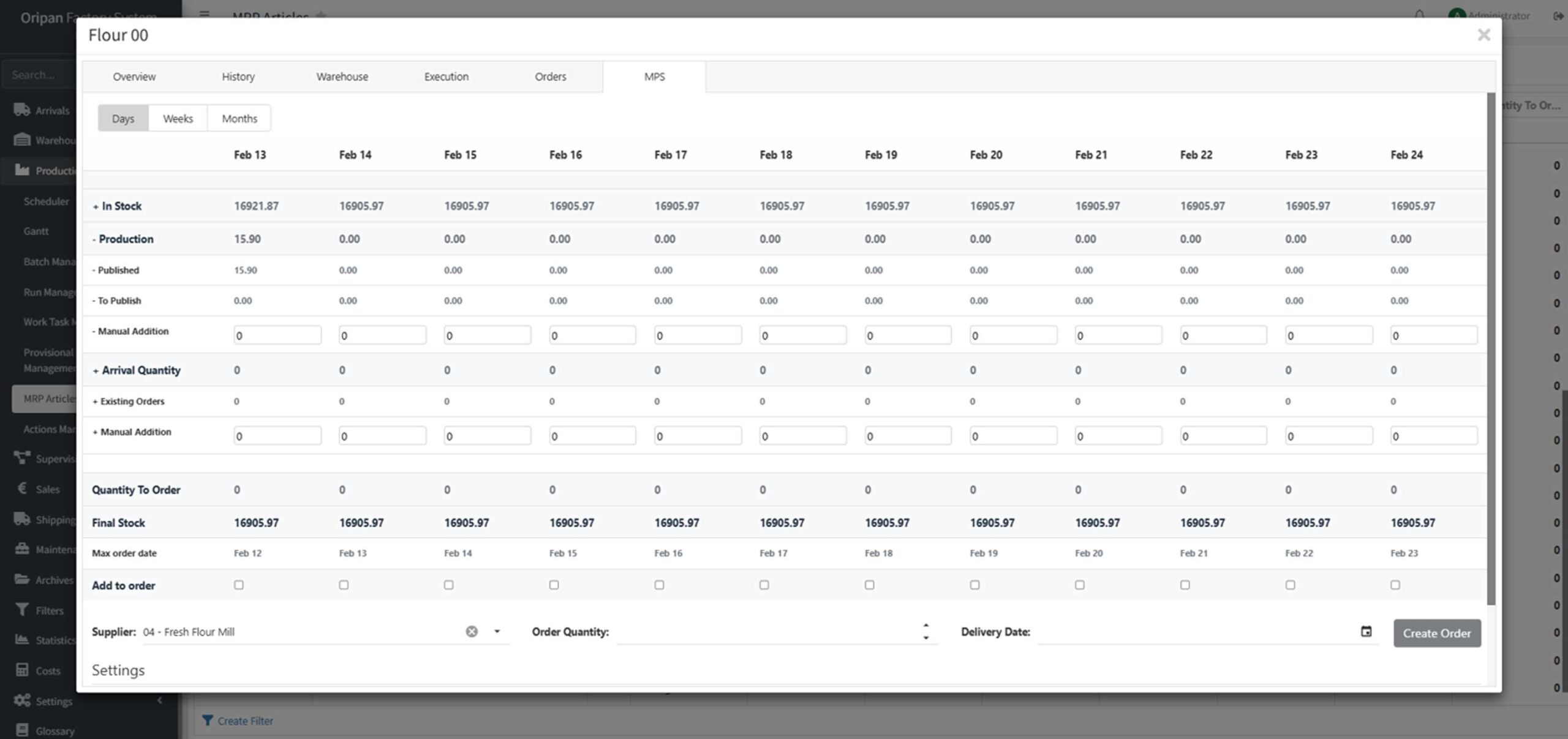

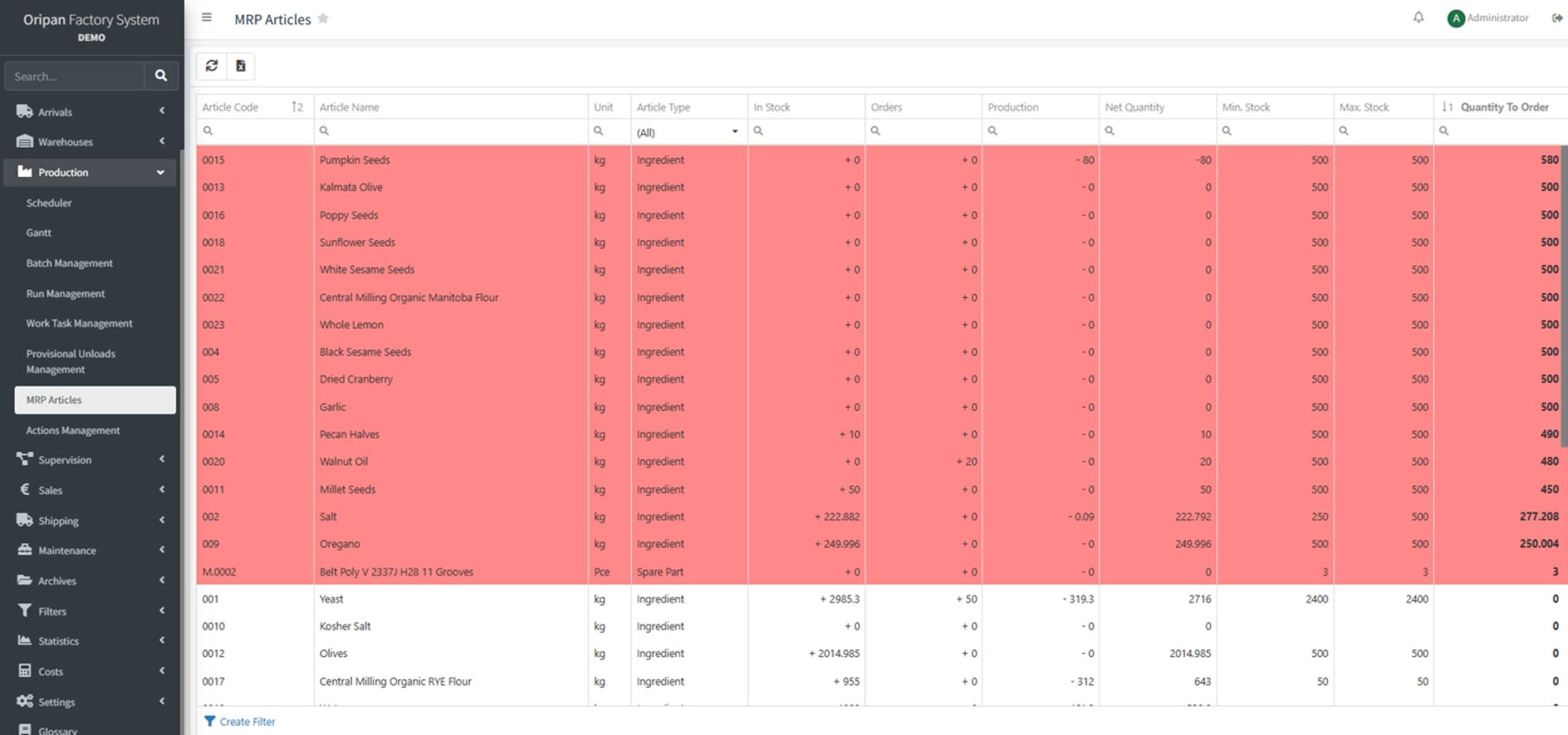

Warehouse

Management

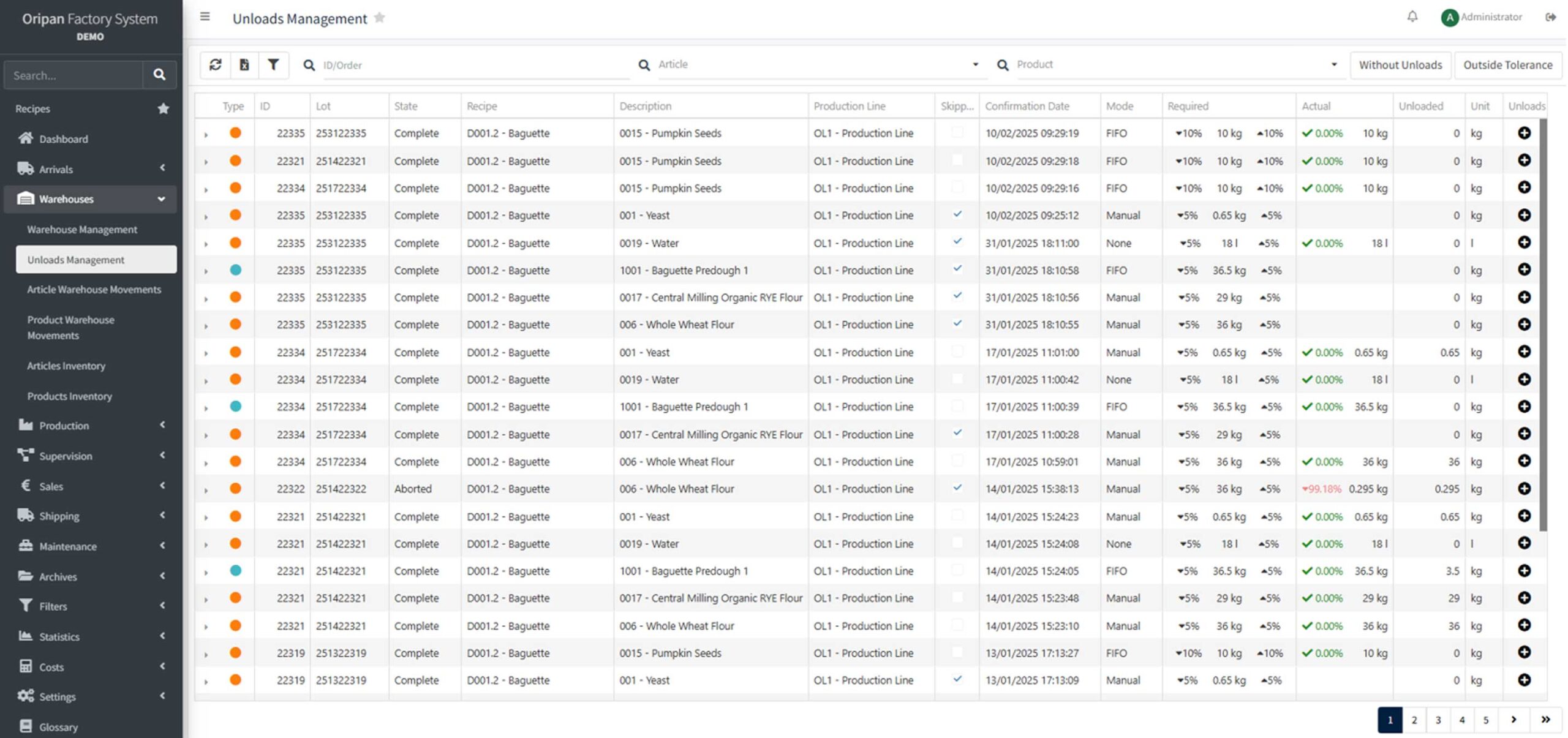

The warehouse module allows the handling of raw materials loads, sub-stocks and automatic reorders through MRP. It also enables automatic discharge of dosed quantity directly from scales in production with automatic check of tolerances.

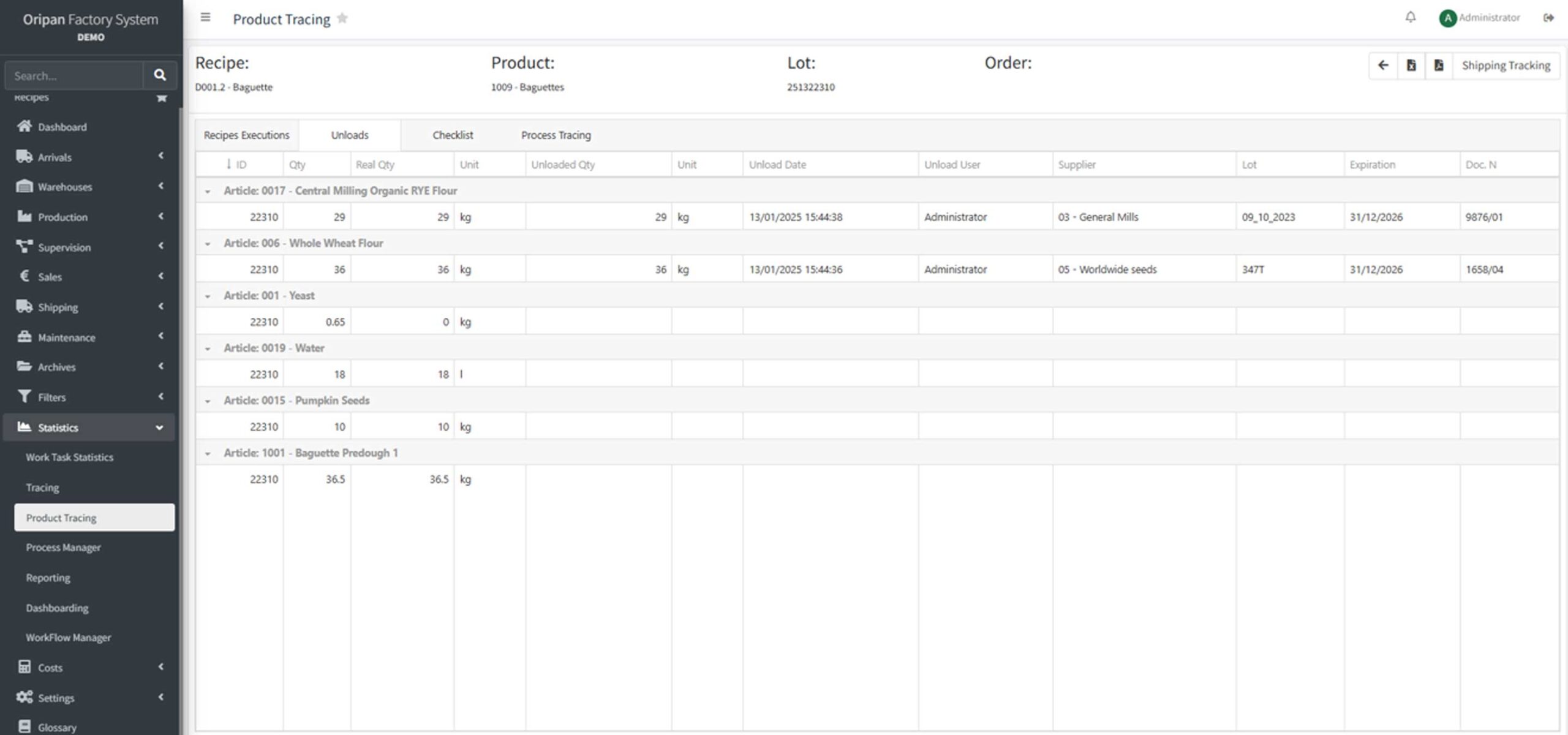

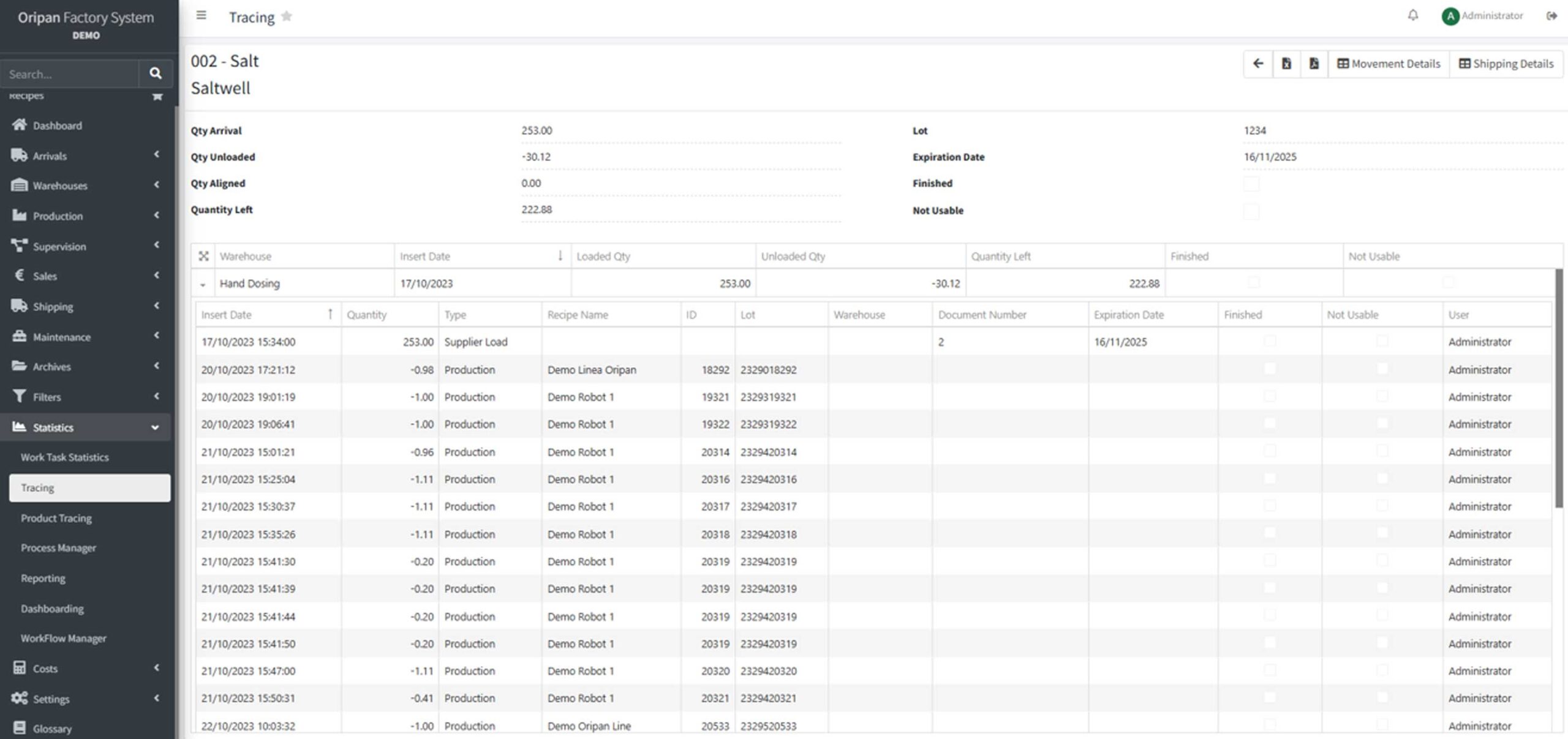

Track & Trace

The system allows to trace the raw and packaging materials, the operations performed by the operator and the processes executed in production in order to have all the useful information to handle any fault and to get statistical data.

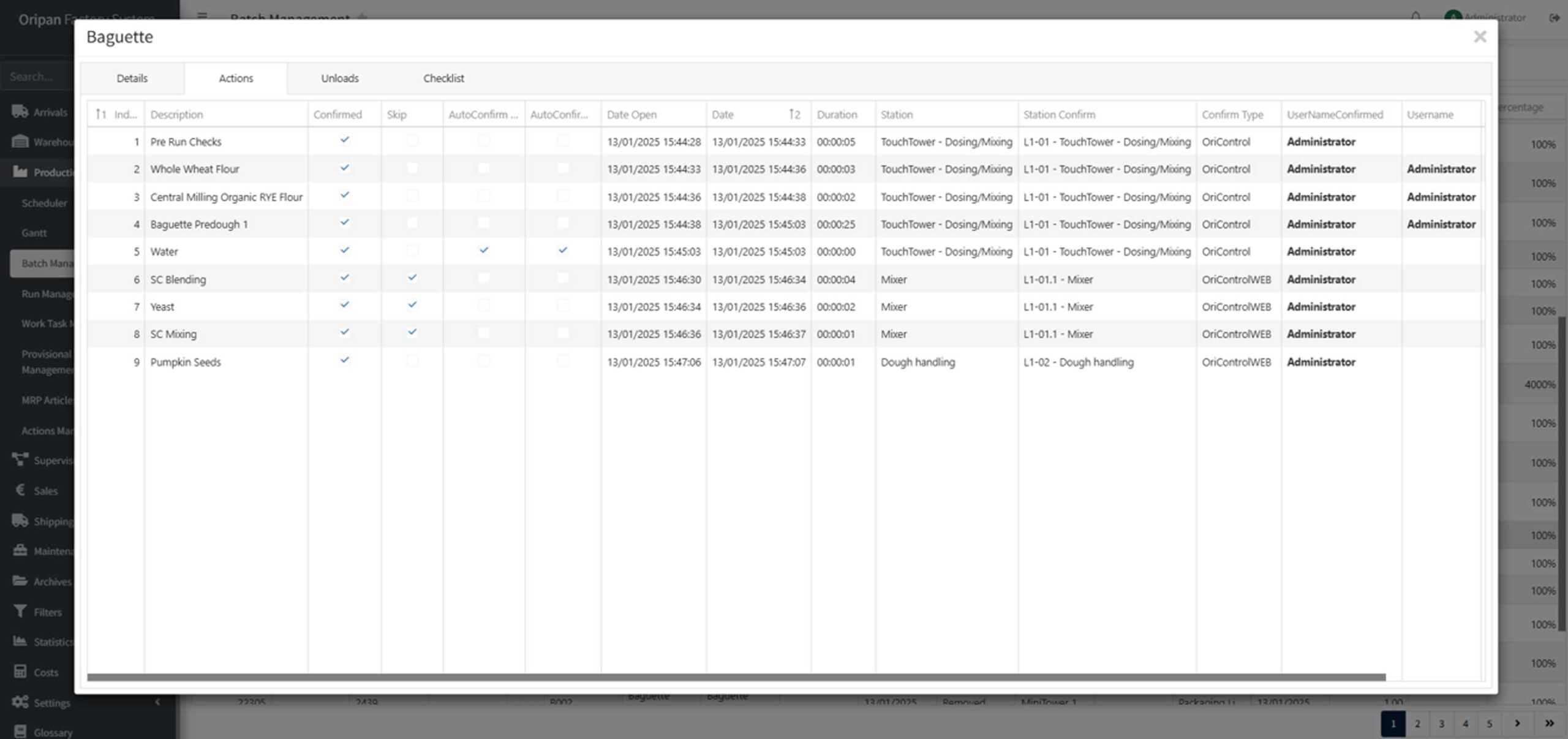

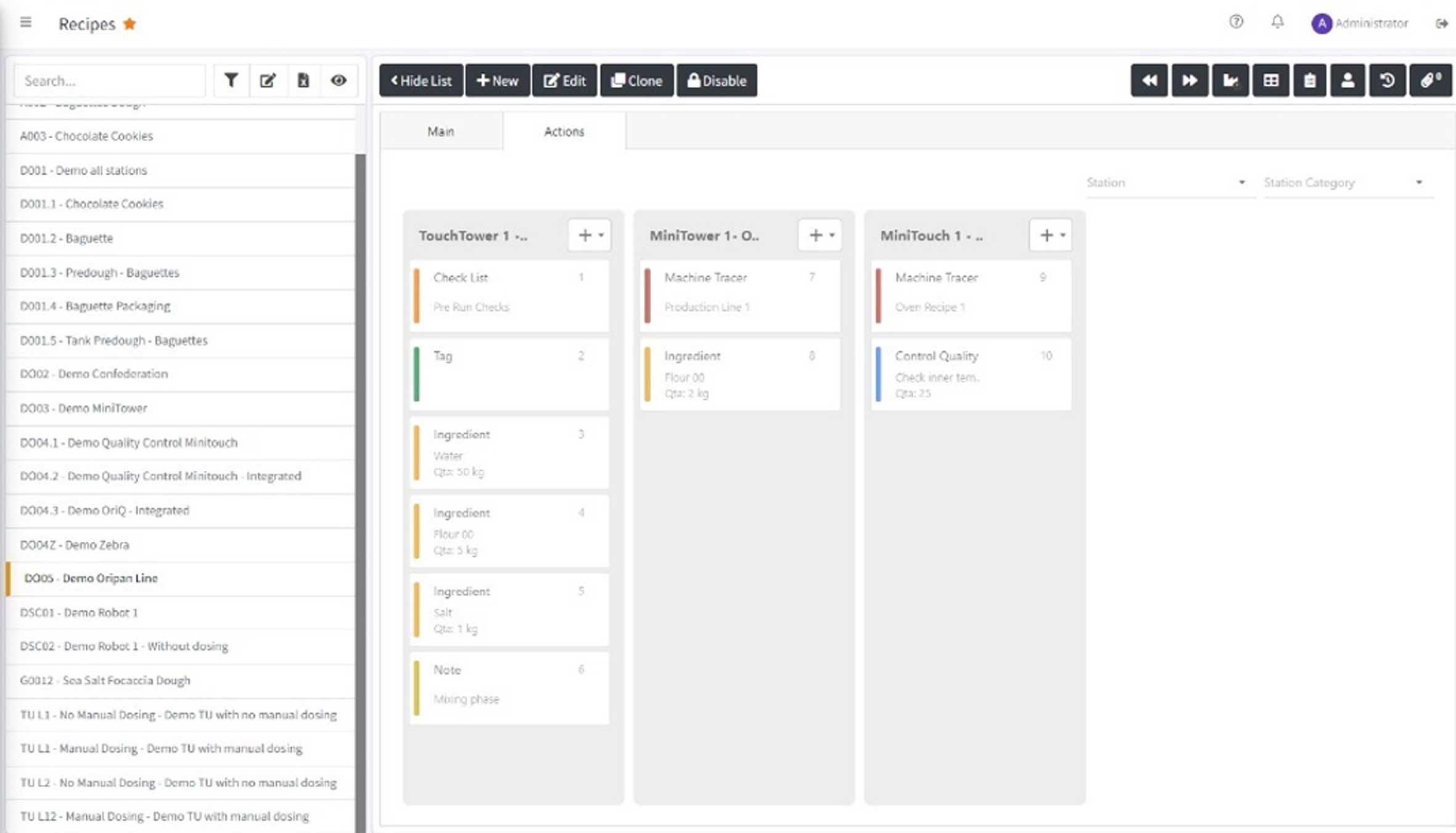

Process Recipes

The system allows to create a process recipe in a simple and intuitive way thanks to an appealing graphic and to a “drag-and-drop” functionality. The process recipe includes ingredients, process actions and machine settings needed to obtain a final product for each station in production.

Production Planning

Functionality for dynamic planning and scheduling of batches in production based on production line availability (shifts, downtimes, other scheduled runs, …). If a recipe is composed of one or more semi-worked products, then when the finished product is scheduled, the semi-worked product is also scheduled. Possibility to monitor real-time production progress comparing scheduled time and speed with actual ones.

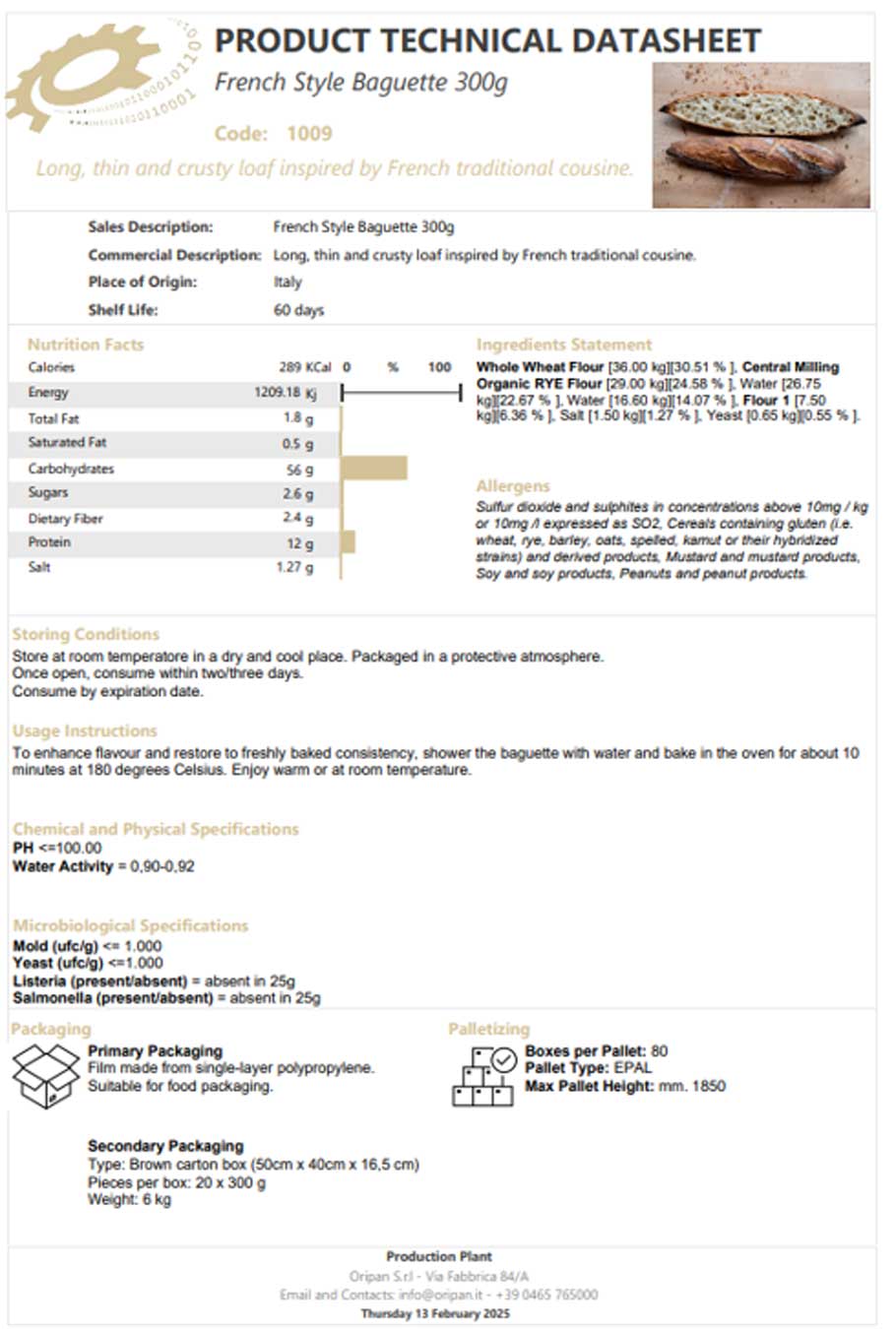

Technical Data Sheets

Creation of finished product technical datasheets with automatic calculation of nutritional values and allergens based on the recipe. The system allows for multilingual and multi-version management of the datasheets. The layout is fully customizable with possibility to add information regarding packaging, chemical, microbiological and physical specifications.

Company Erp Integration

Possibility to integrate with company existing ERP through API or other solutions to exchange needed information.

Production

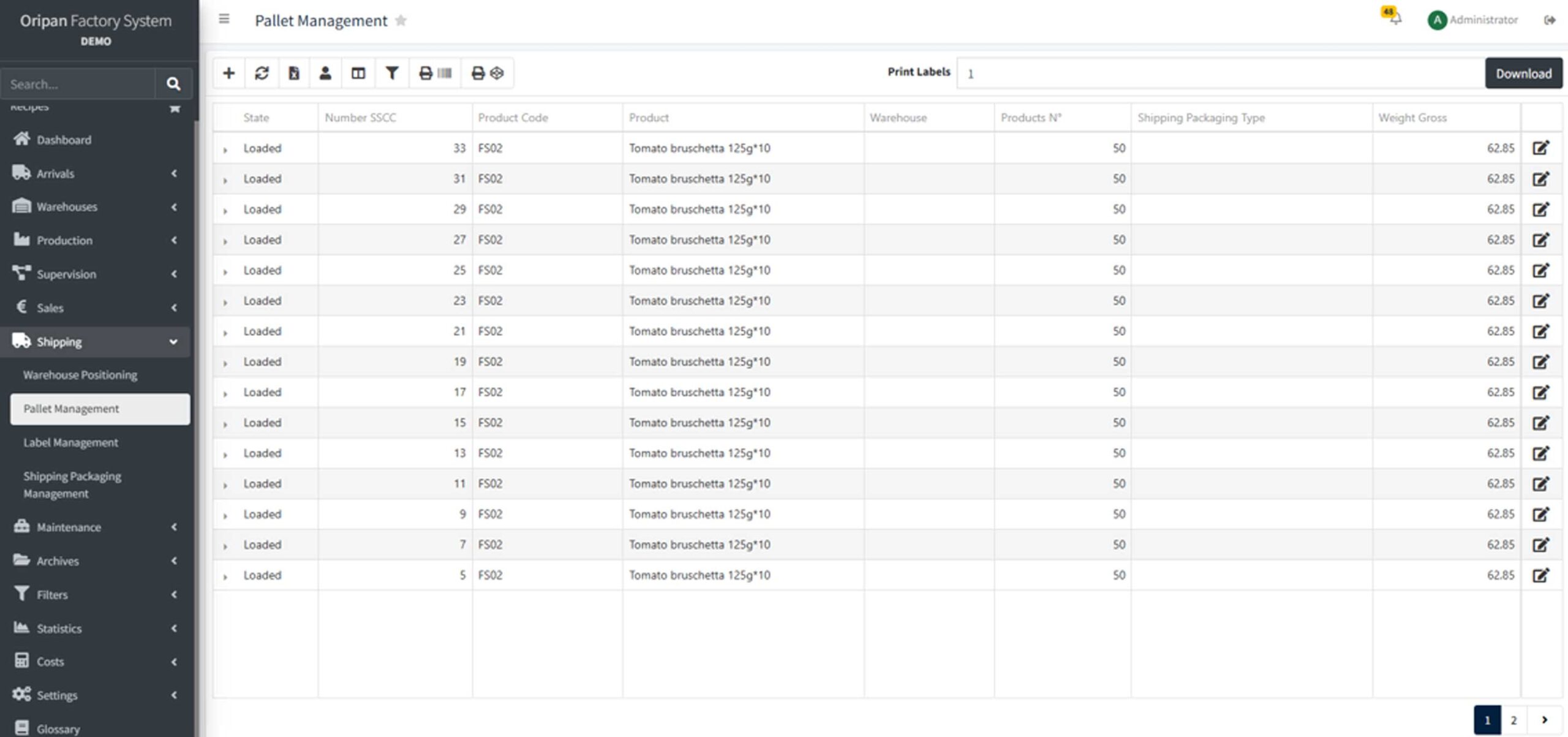

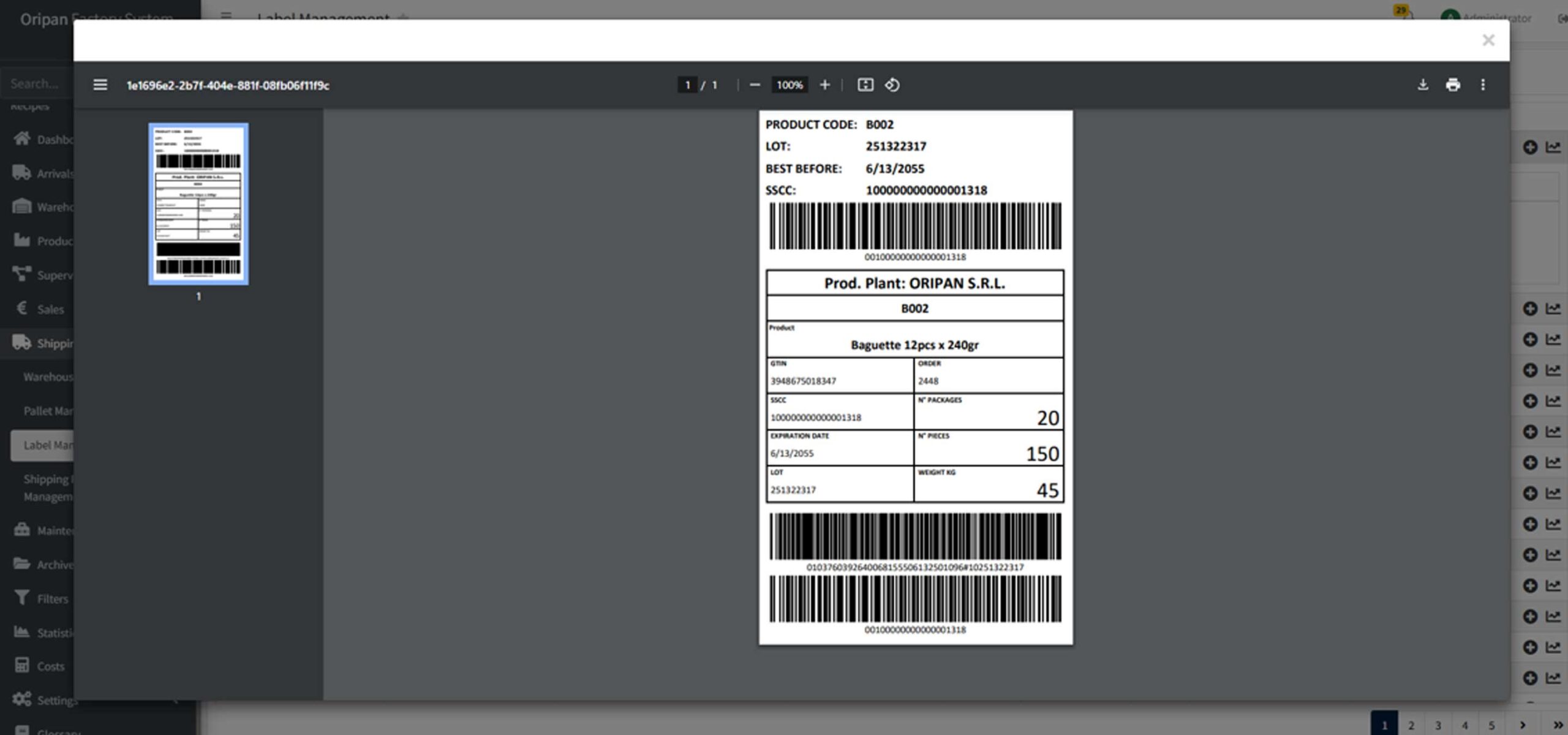

Packaging

Management of primary packaging to communicate production batches to markers, unload and track first-contact materials, and collect data such as product weight, produced units, scraps, and line speed. For secondary packaging, registration and printing of carton and pallet labels, including all necessary traceability information and GTIN for distribution. Possibility to manage shipping packaging to track pallets that still need to be returned by clients.

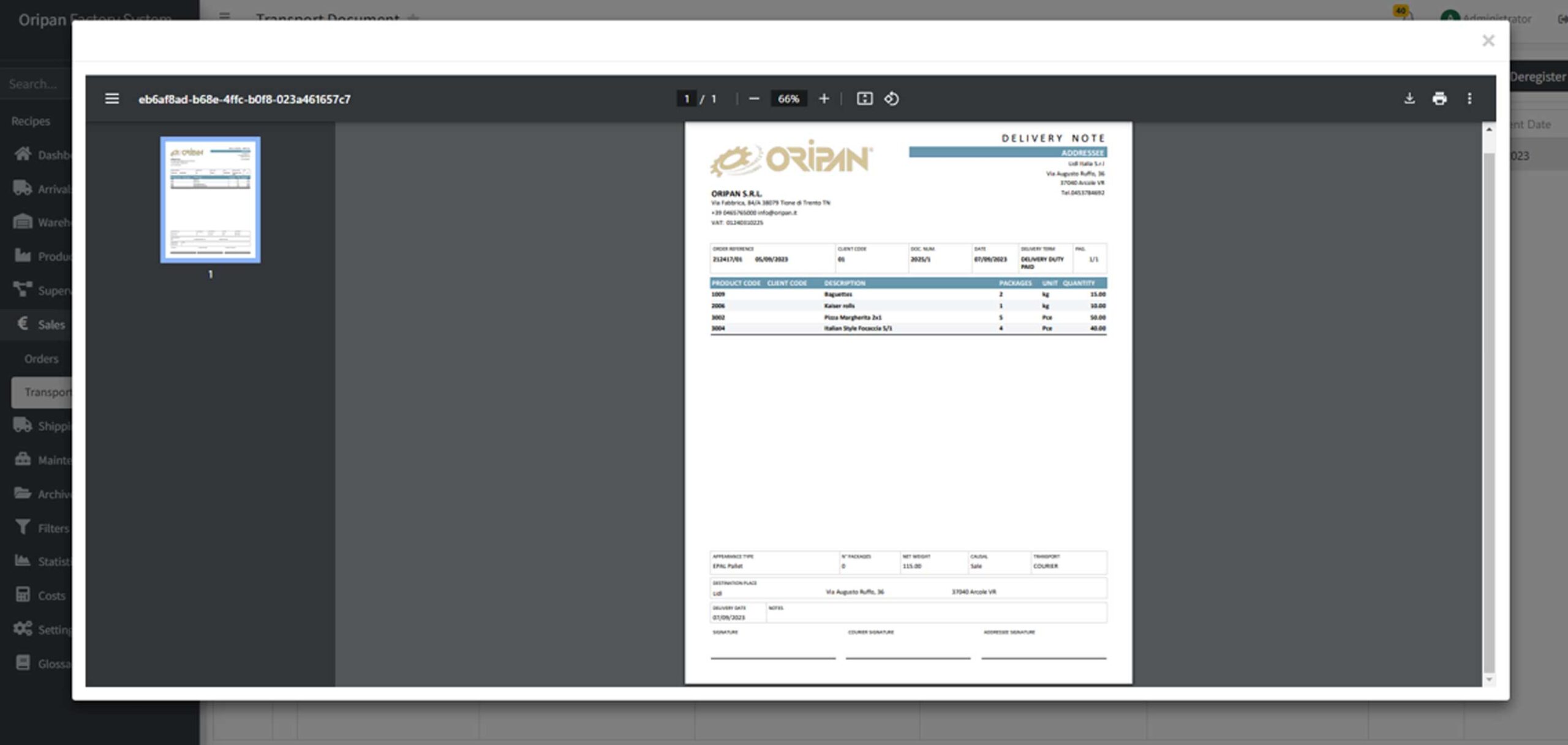

Final Products Picking and Delivery

Guided product picking based on customer order with emission of transport document and packaging list. Automatic alignment of finished product warehouse based on delivered final products.

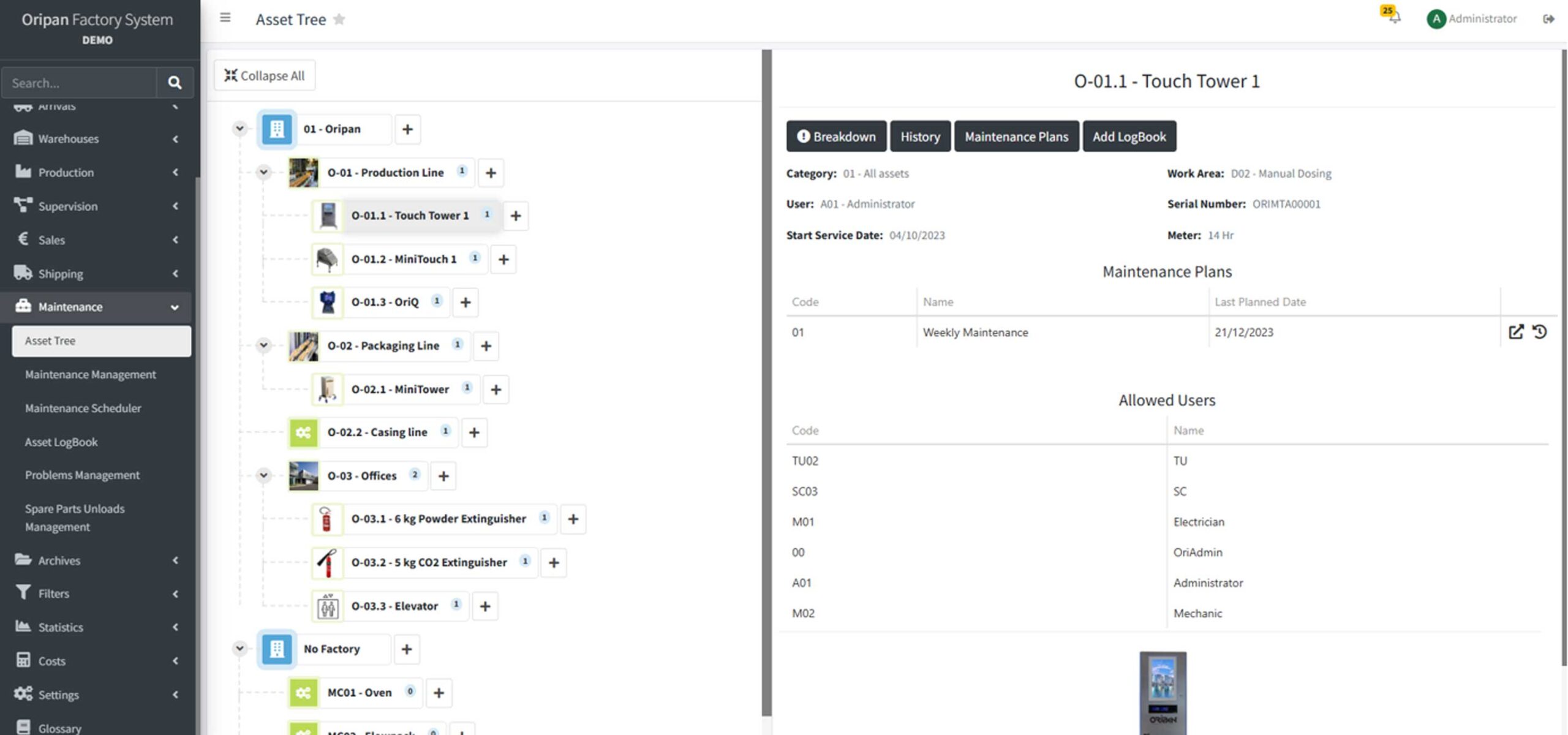

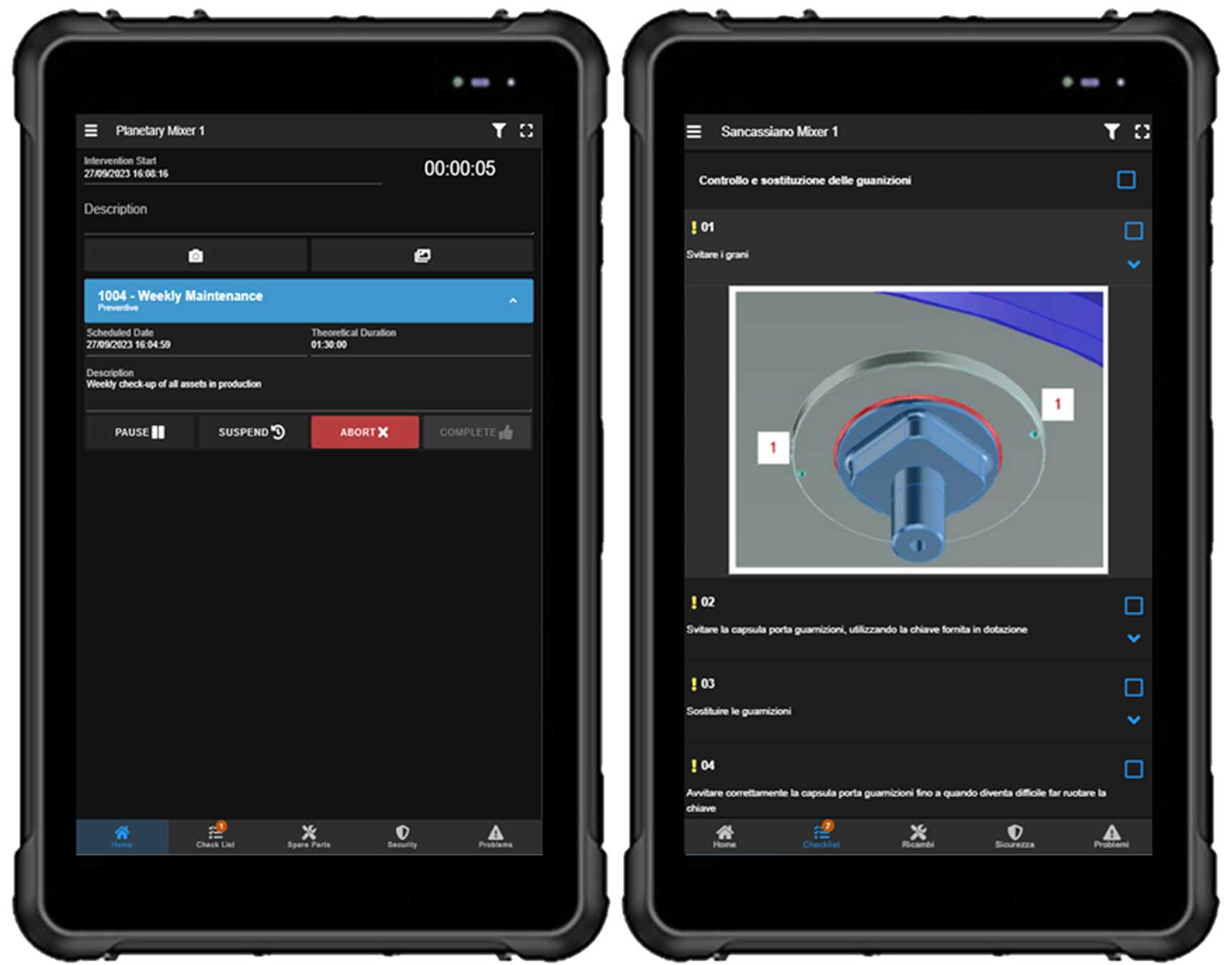

Maintenance Management

Maintenance module for the management of spare parts warehouse, preventive maintenance and breakdowns of all machinery and other equipment within the factory and offices. Each assets is associated with its maintenance plans which include maintenance activities, spare parts, PEEs, tools and risk factors. The feature tracks the execution of each maintenance plan with timing, spare parts used and signaled problems. Breakdowns and improvements can also be signaled from our hardware in production to open a ticket for maintenance department.

Analysis

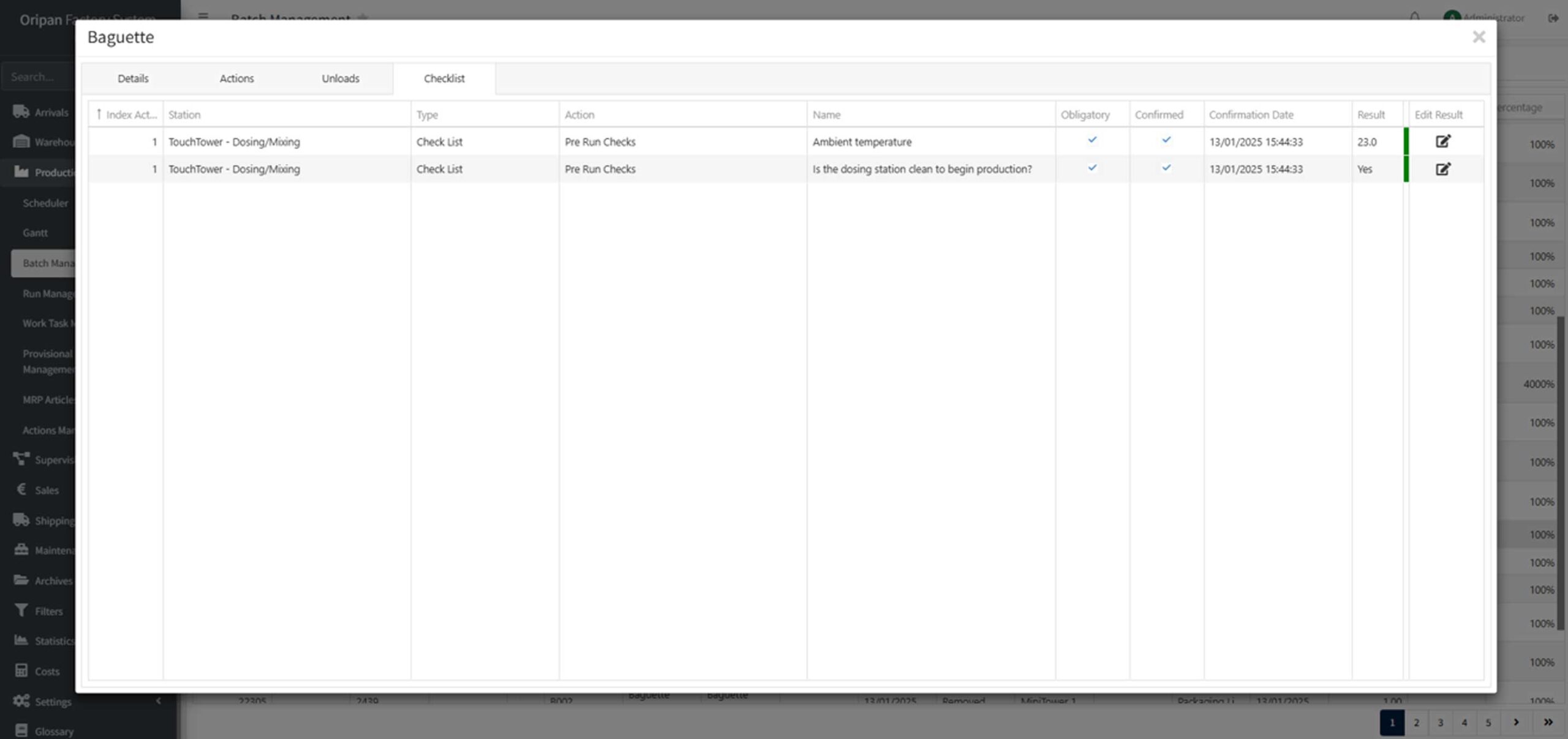

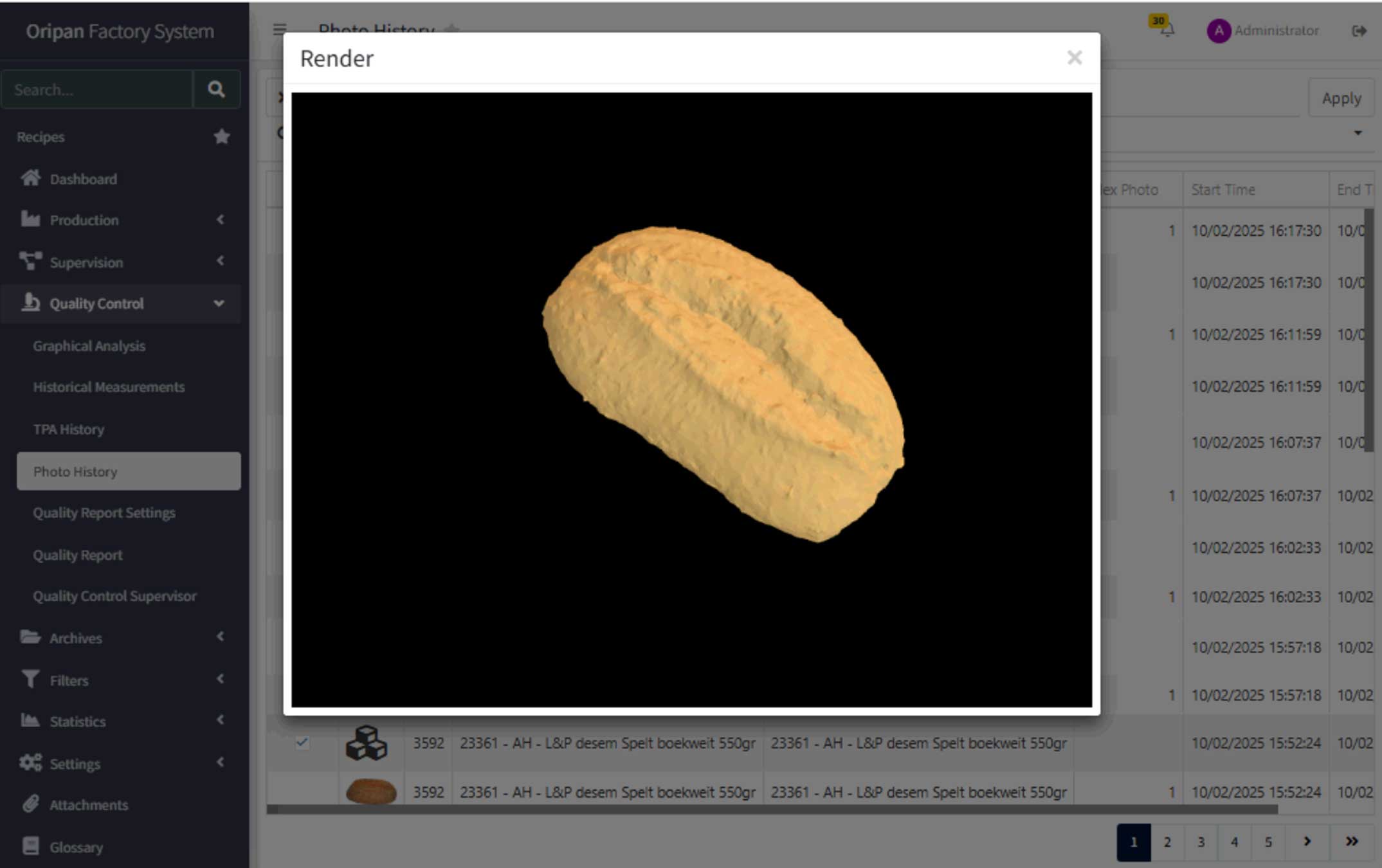

Quality Controls

Integrated quality controls of dough and finished products including check lists, weight & temperature controls, vision systems and automated real-time quality control though OriQ.

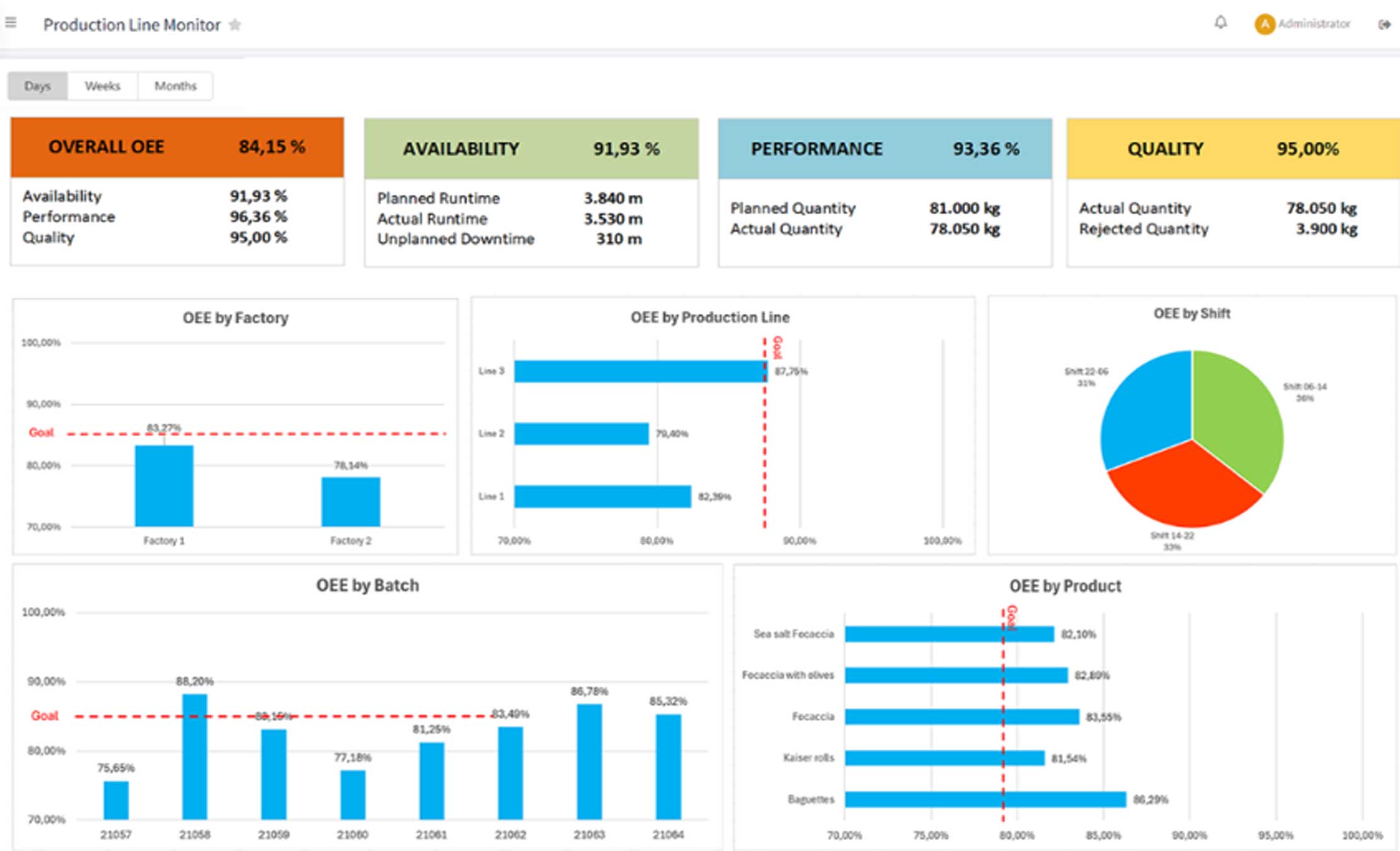

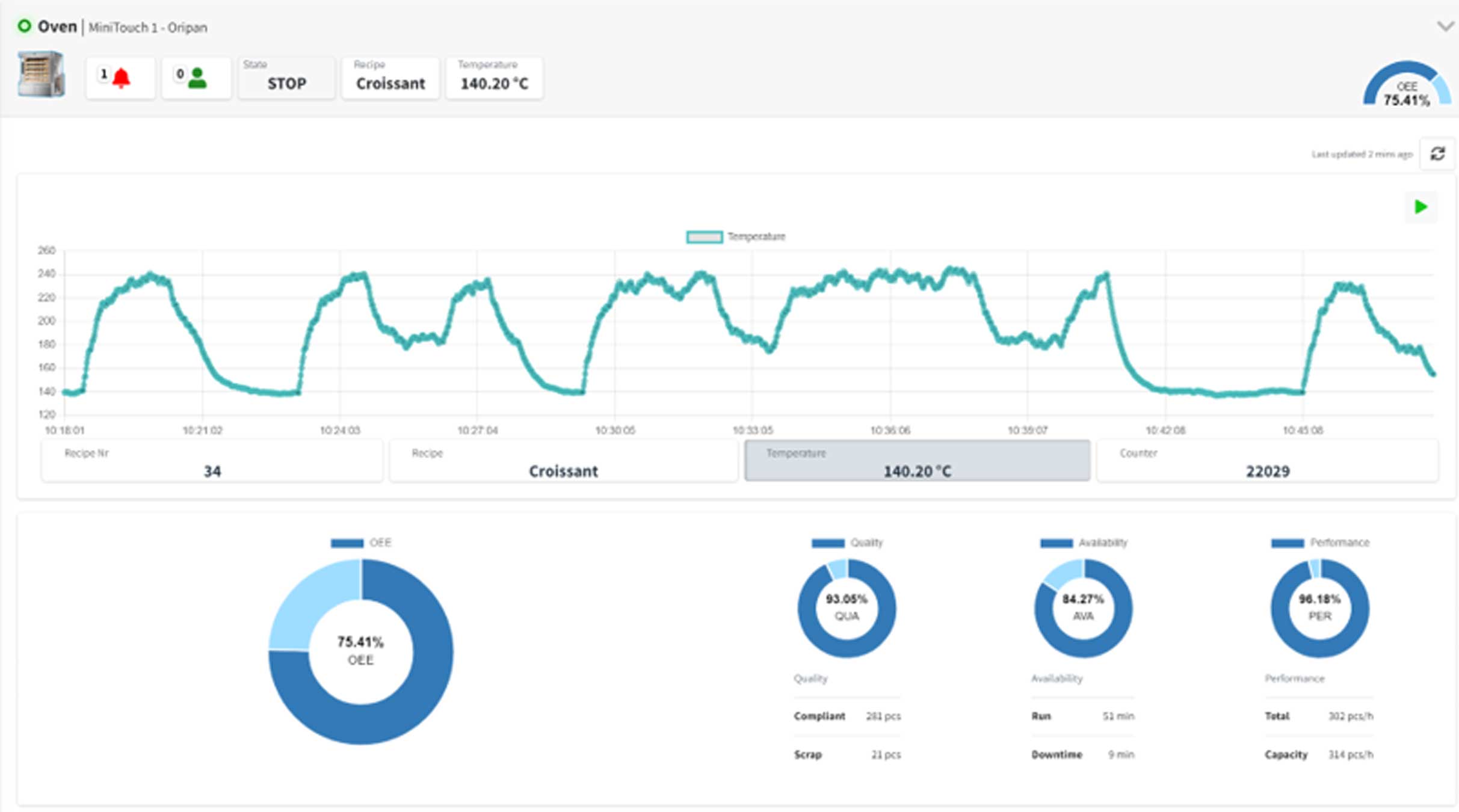

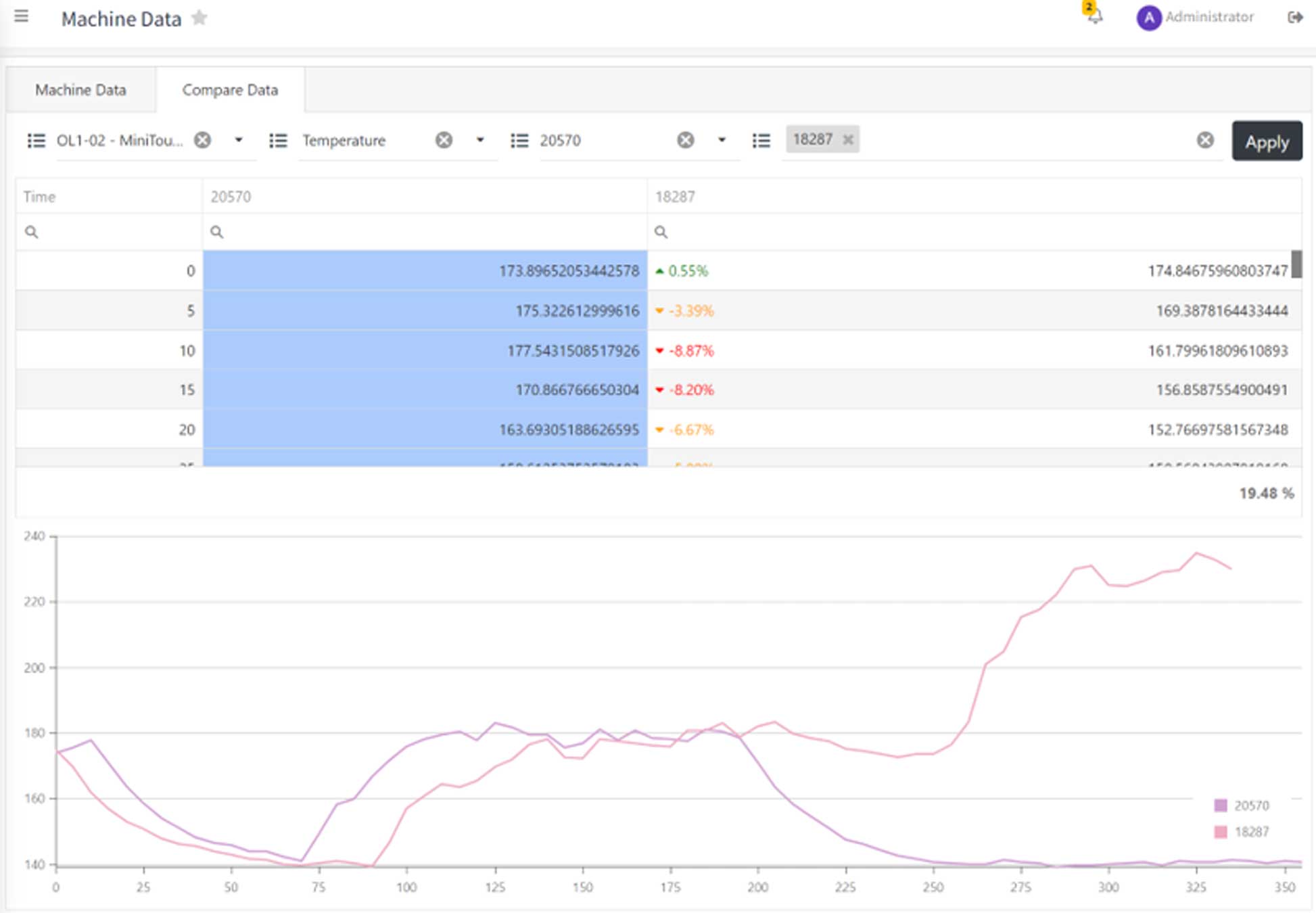

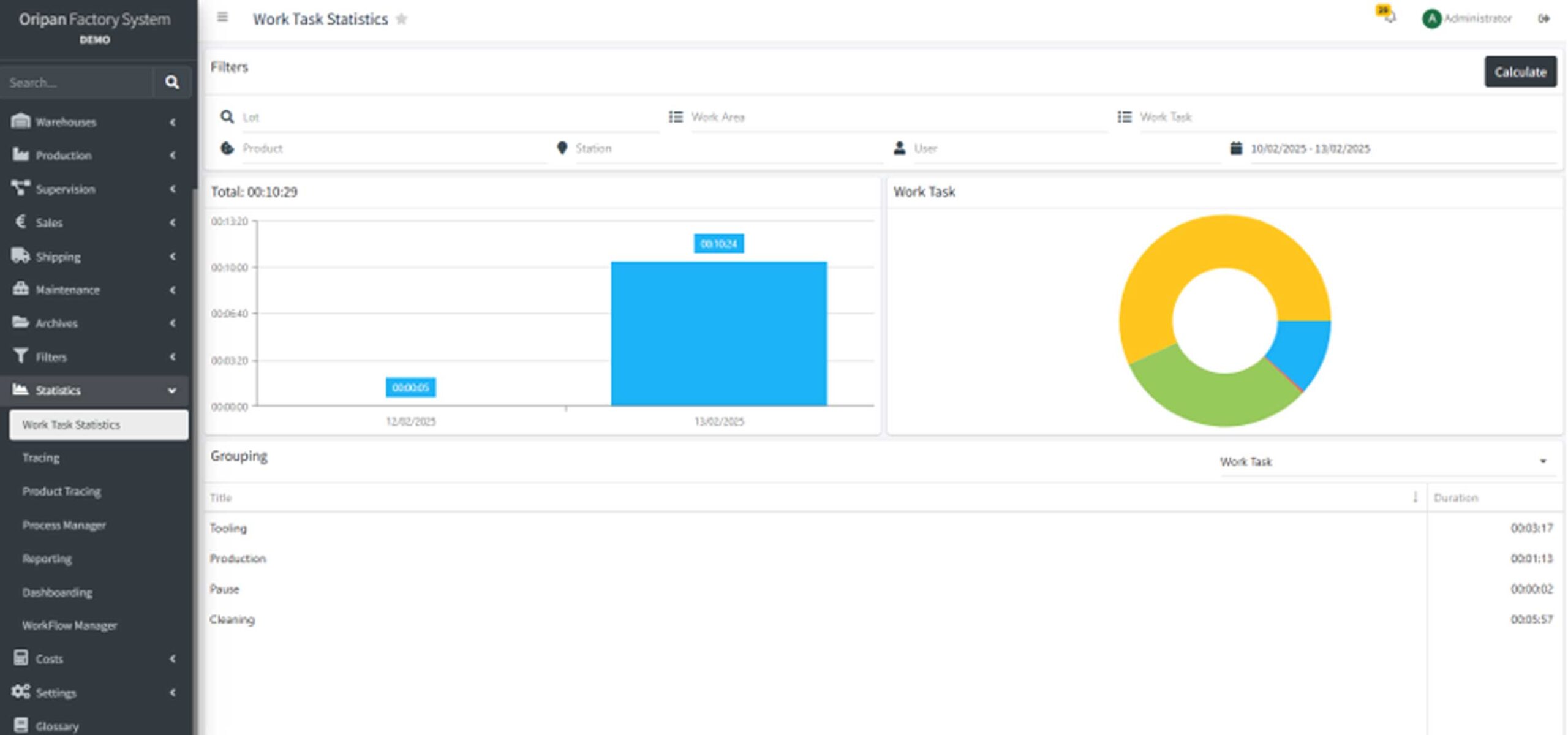

Production Supervision and kpi

Personalized reports and dashboards to display production statistics and KPIs for production processes. Possibility to monitor production progress, machinery status and alarms and related process data batch by batch.

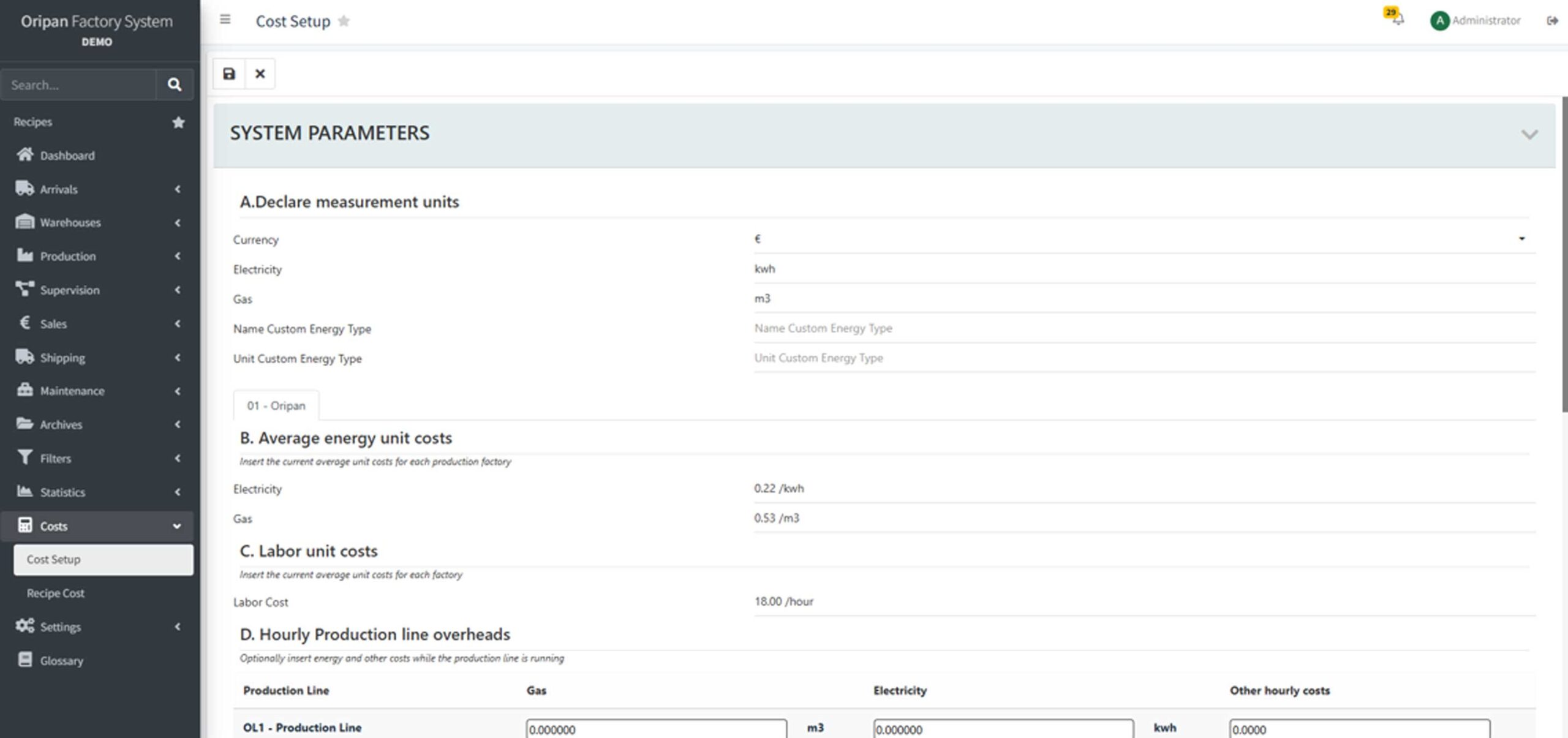

Production Cost Calculation

Feature to calculate the primary cost of product manufacturing, including raw materials, labor, and energy. It calculates both the theoretical and actual production costs of the recipe, covering directly attributable costs as well as production-related costs, excluding overhead expenses.

We prioritize security and availability

Securing industrial systems against digital threats demands a robust commitment to availability, integrity, and confidentiality. Our approach ensures maximum security and performance through:

- Continuous updates to meet the latest technological and security standards.

- Scalable architecture, both vertically (adding resources as needed) and horizontally (distributing services across multiple servers).

- High availability setup to minimize downtime and ensure system resilience.

- Tailored security strategies, designed in collaboration with our clients to protect sensitive data.

- Flexible deployment options, offering both on-premise and Cloud solutions to suit your operational needs.

With these measures, we provide a secure, high-performance infrastructure that adapts to your business needs.

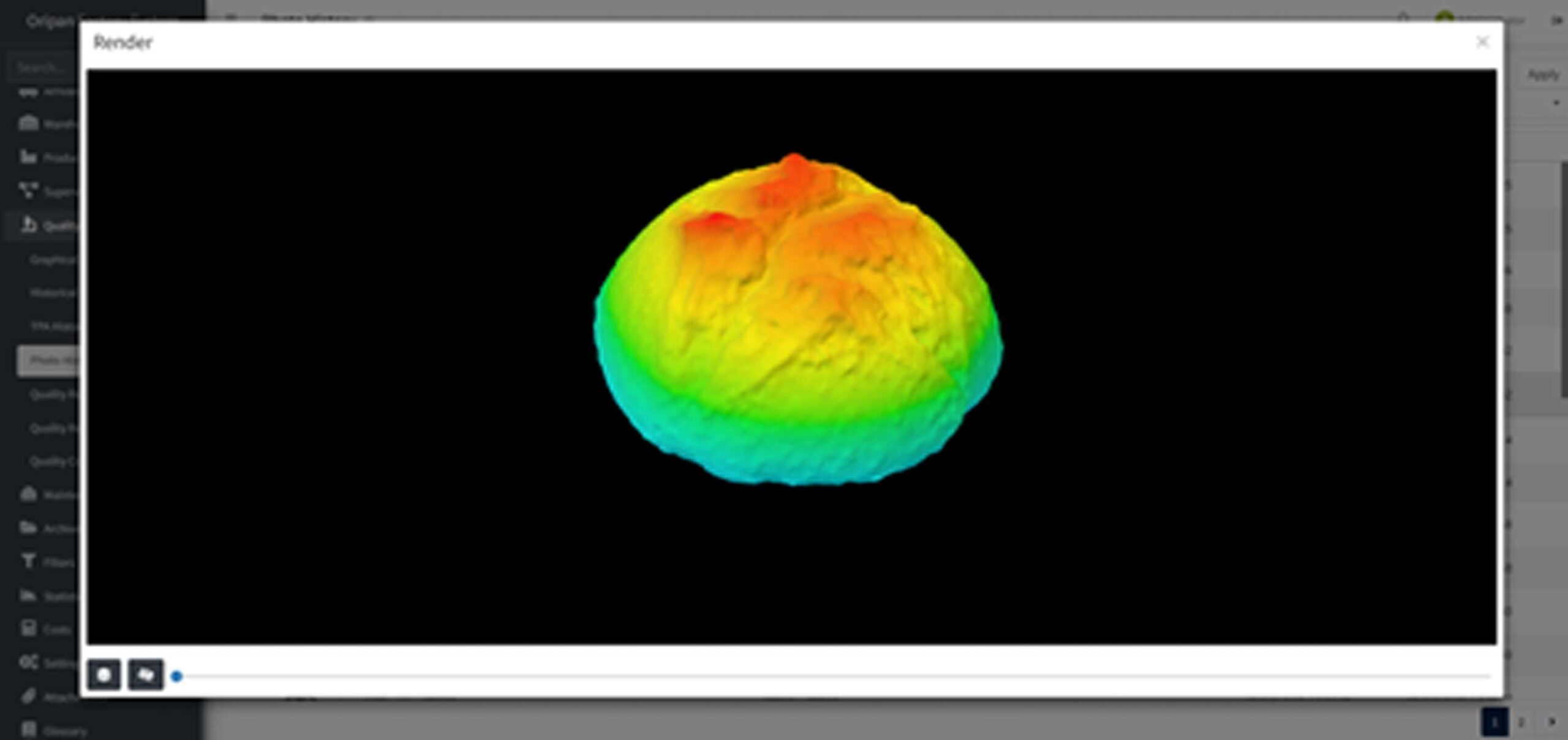

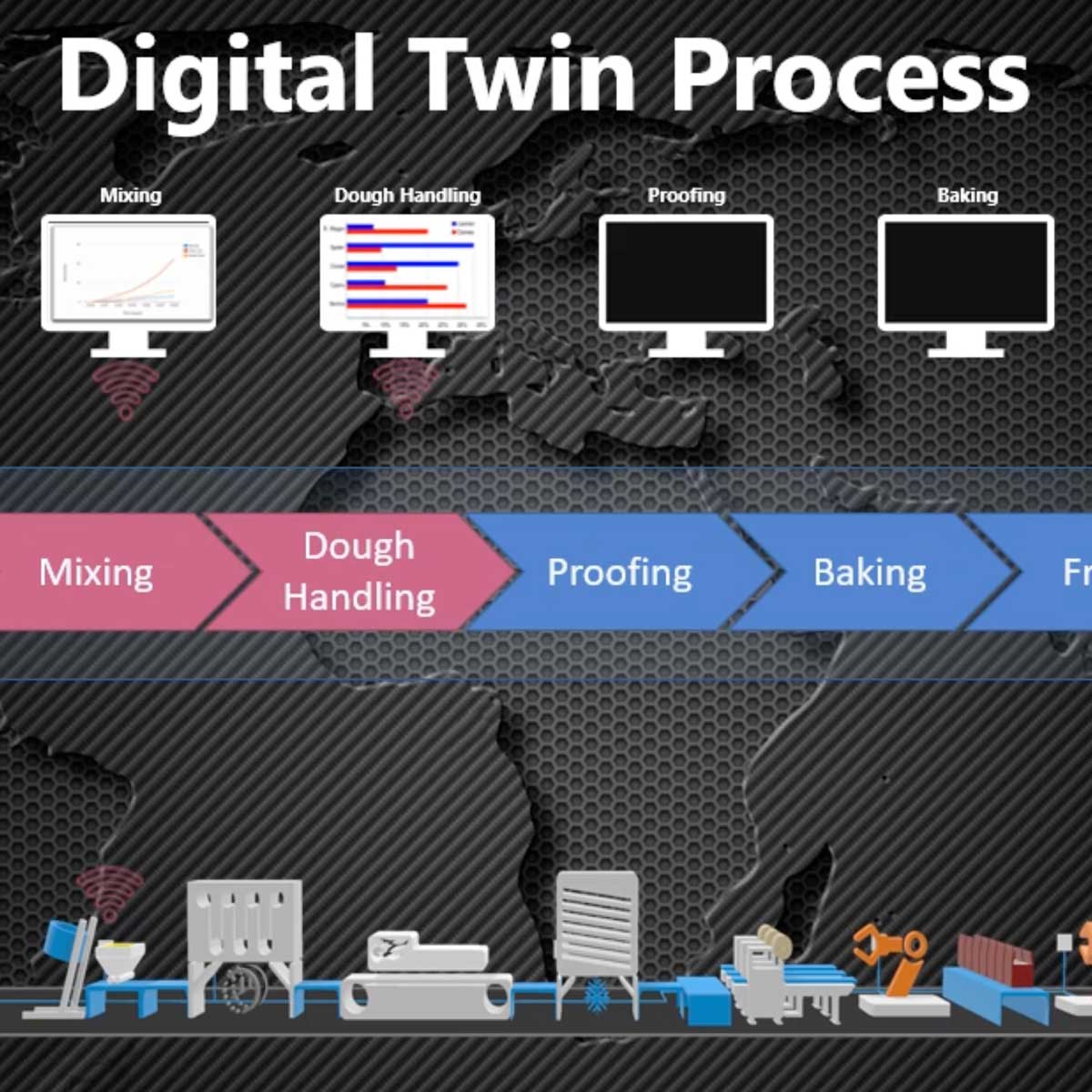

The Digital Twin of your production process

The OFS system is able to generate a digital process parallel to the real system, the Digital Twin, i.e. making the virtual replication process elaborating the same inputs that are supplied to the real system. OFS is able to trace in real time the production process on all production lines verifying the operating conditions under which it is performed.

Inside our platform: a visual tour of the software

OFS stands out for its user-friendly design and ease of use. Its intuitive interface, clear navigation, and organized layout make it simple for users to access information and perform tasks efficiently, even with minimal training.