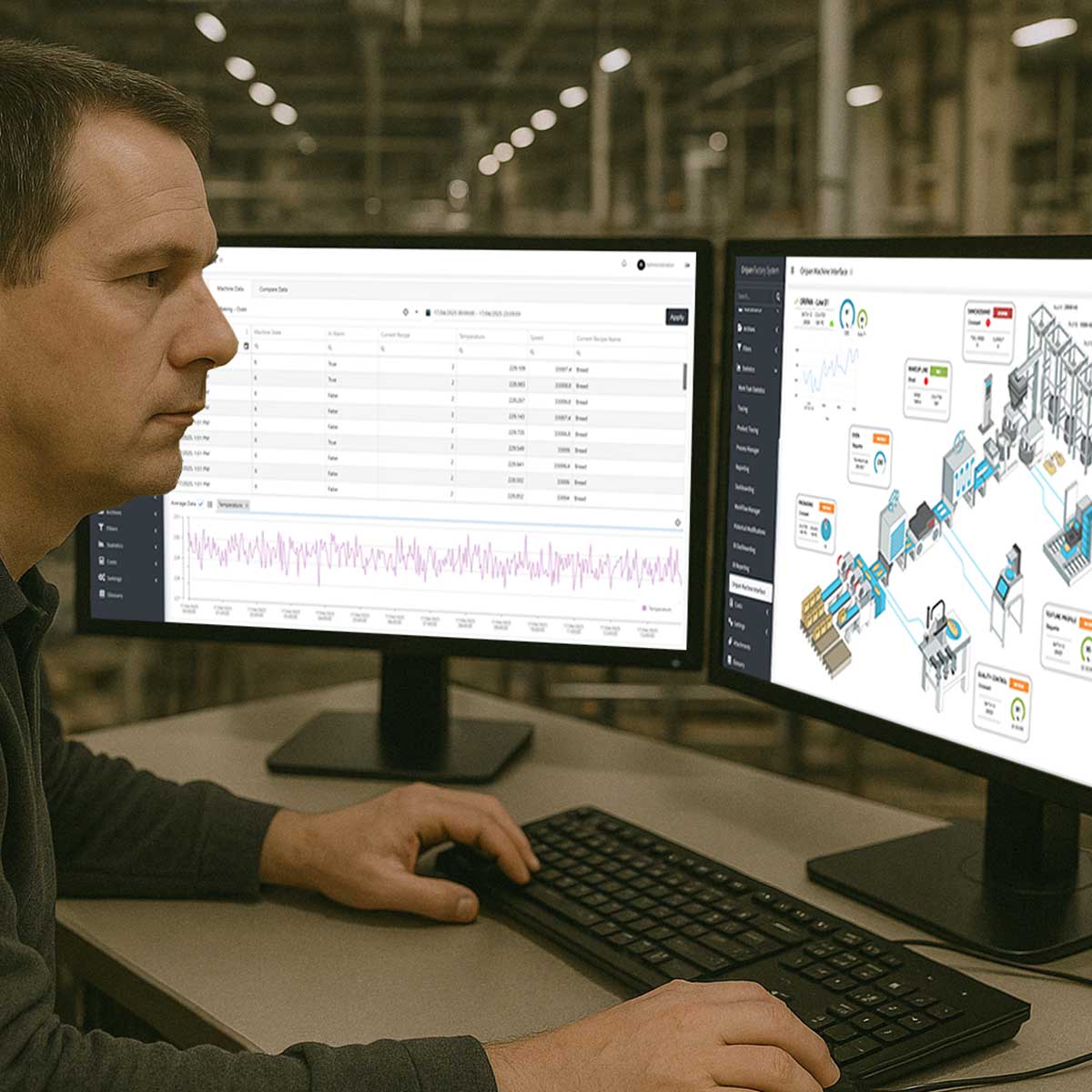

One of the biggest challenges in the bakery industry is breaking the information barrier between management and the production floor. Manual data collection and siloed information prevent full visibility over batch tracking, machine performance, and operator efficiency, making it harder to optimize processes.

Our production gateways provide full shop floor integration, enabling real-time batch tracking across automatic, semi-automatic, and manual processes. They facilitate machine data collection and integration, allowing for precise recipe execution, equipment monitoring, alarm detection, and statistical analysis.