In the modern bakery industry, digitalized and automated quality control is essential for ensuring consistency, efficiency, and traceability throughout production. Manual inspections are prone to human error, variability, and delays, making it difficult to maintain uniform product quality.

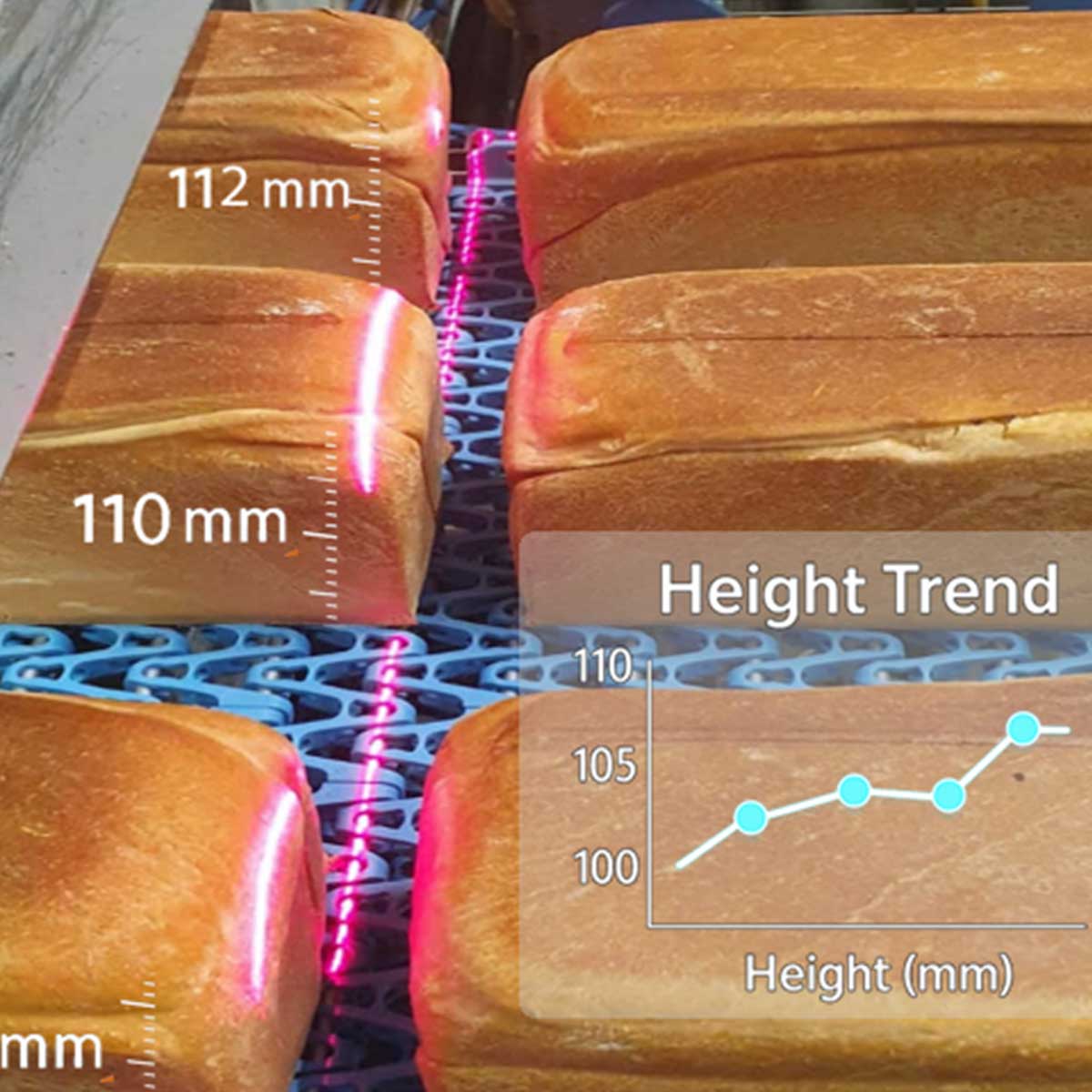

Automated systems provide real-time monitoring and data collection, allowing for immediate detection and correction of deviations before they impact the final product.