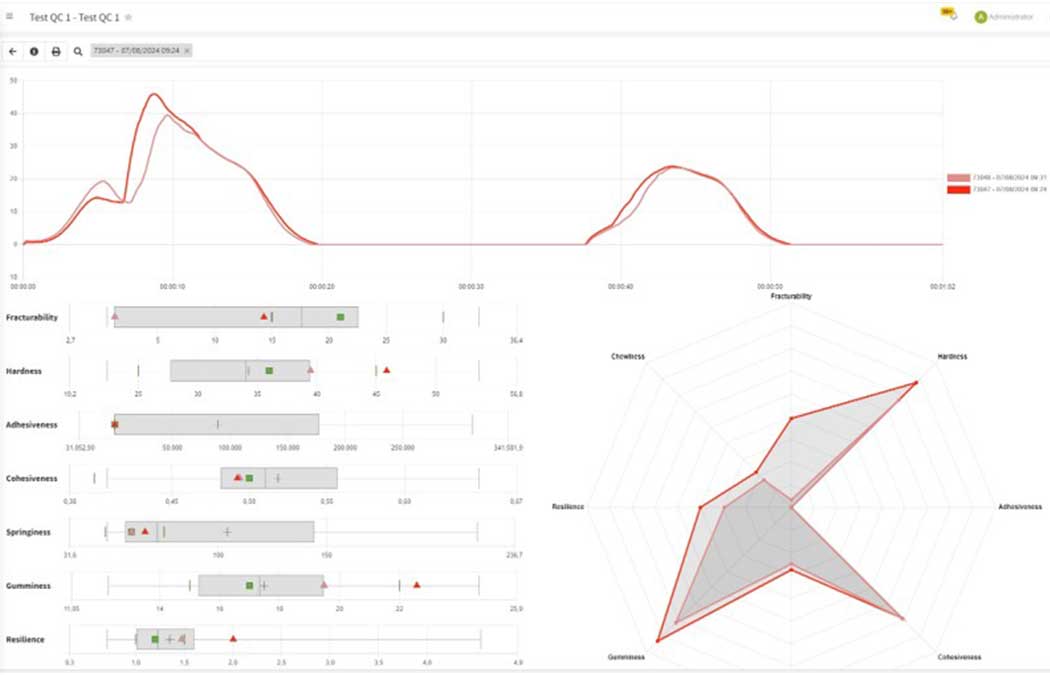

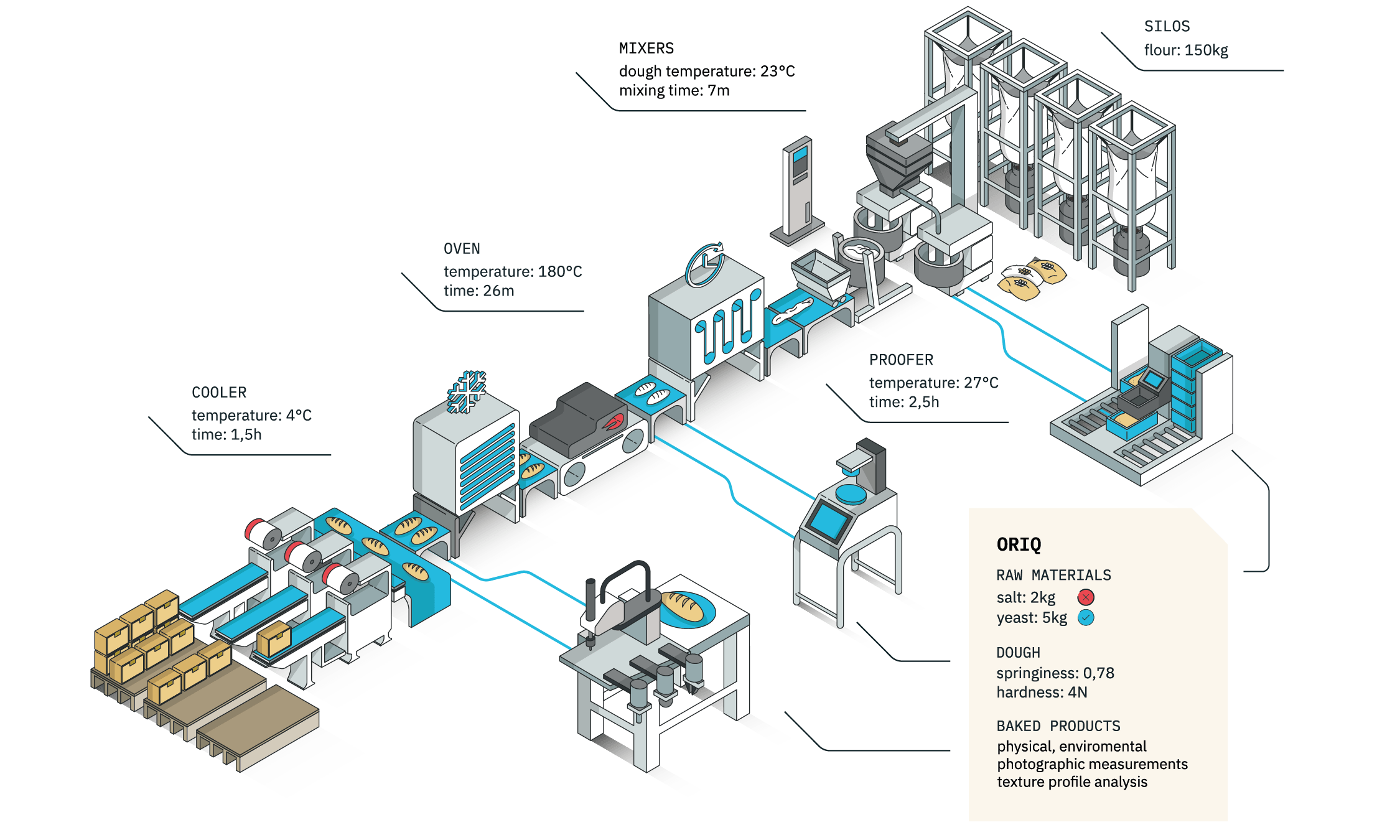

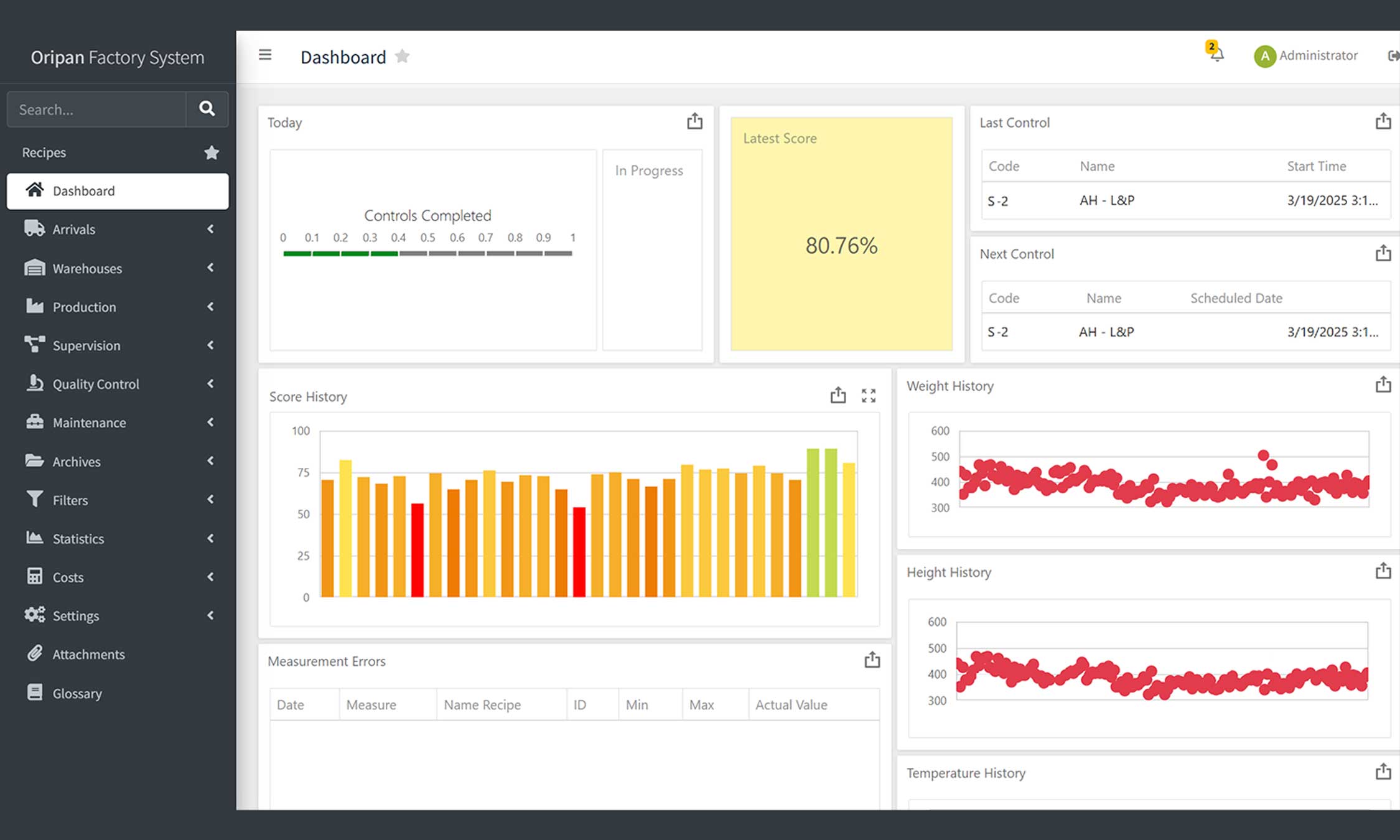

OriQ BakedProducts redefines quality control by moving beyond the traditional pass/fail assessment of individual products. Instead, it provides an objective, real-time evaluation of product quality through multiple measurement methods. This approach not only ensures final product compliance but also drives process standardization and continuous improvement, enhancing overall production efficiency.

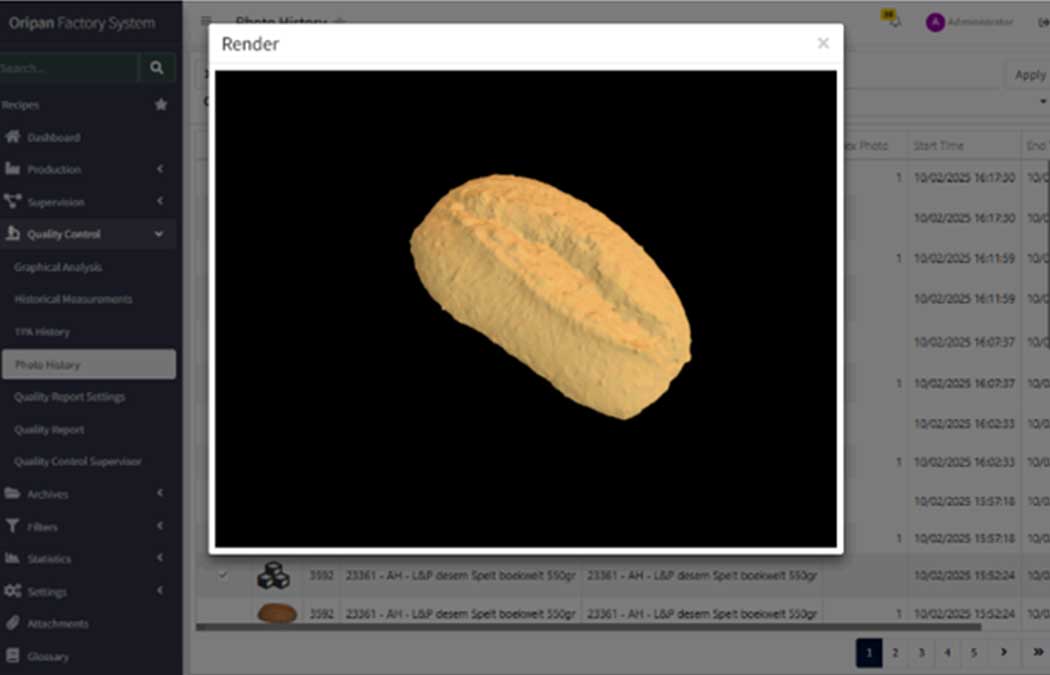

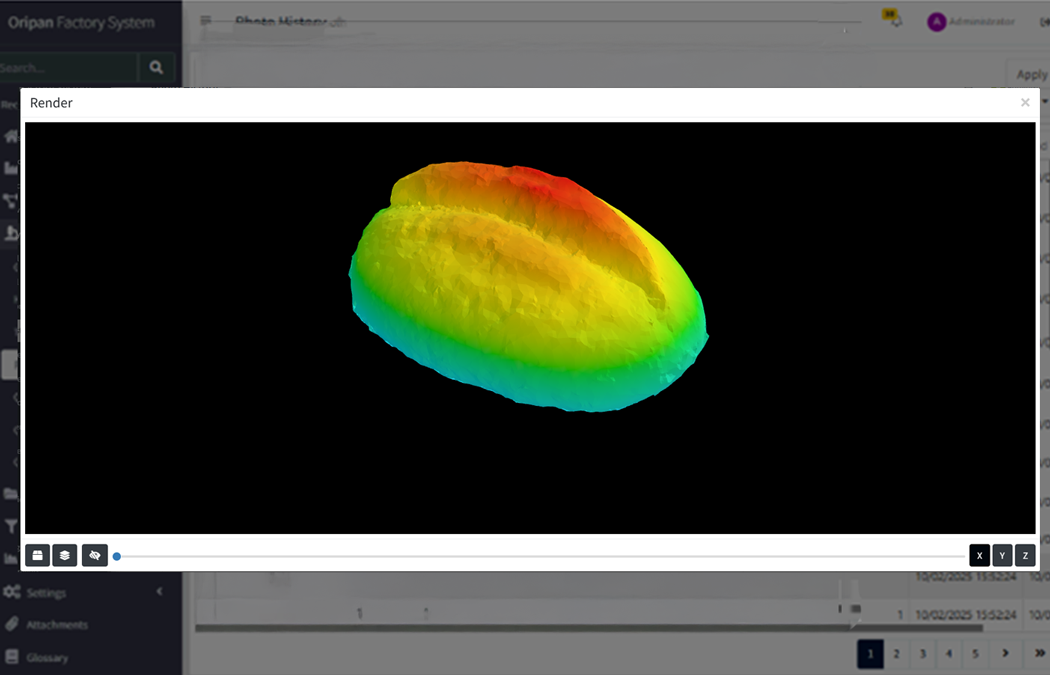

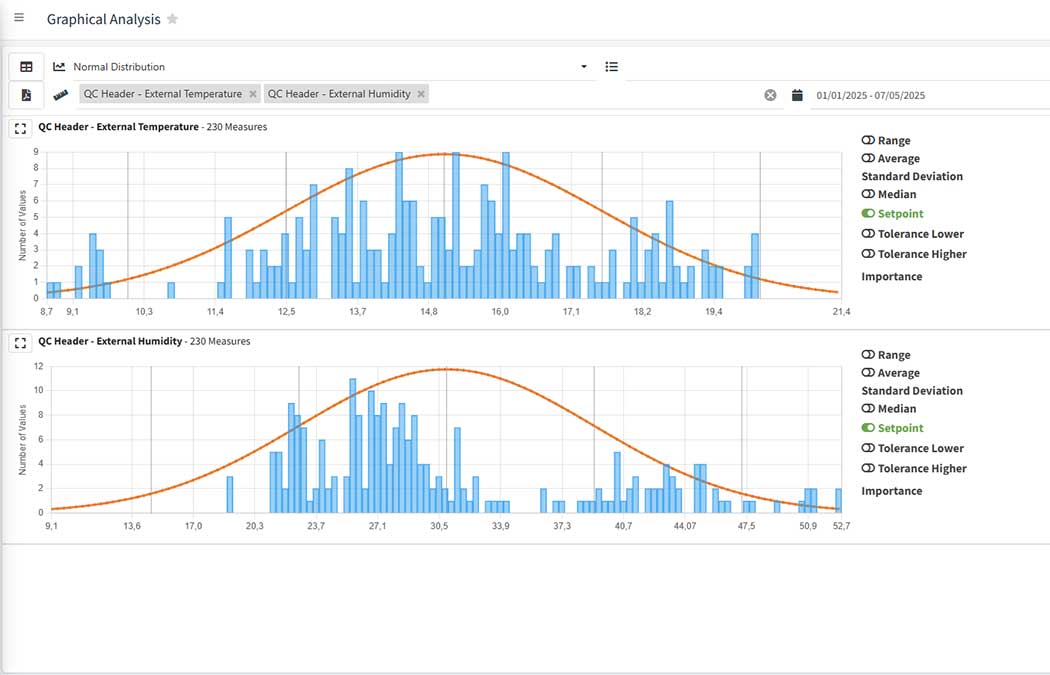

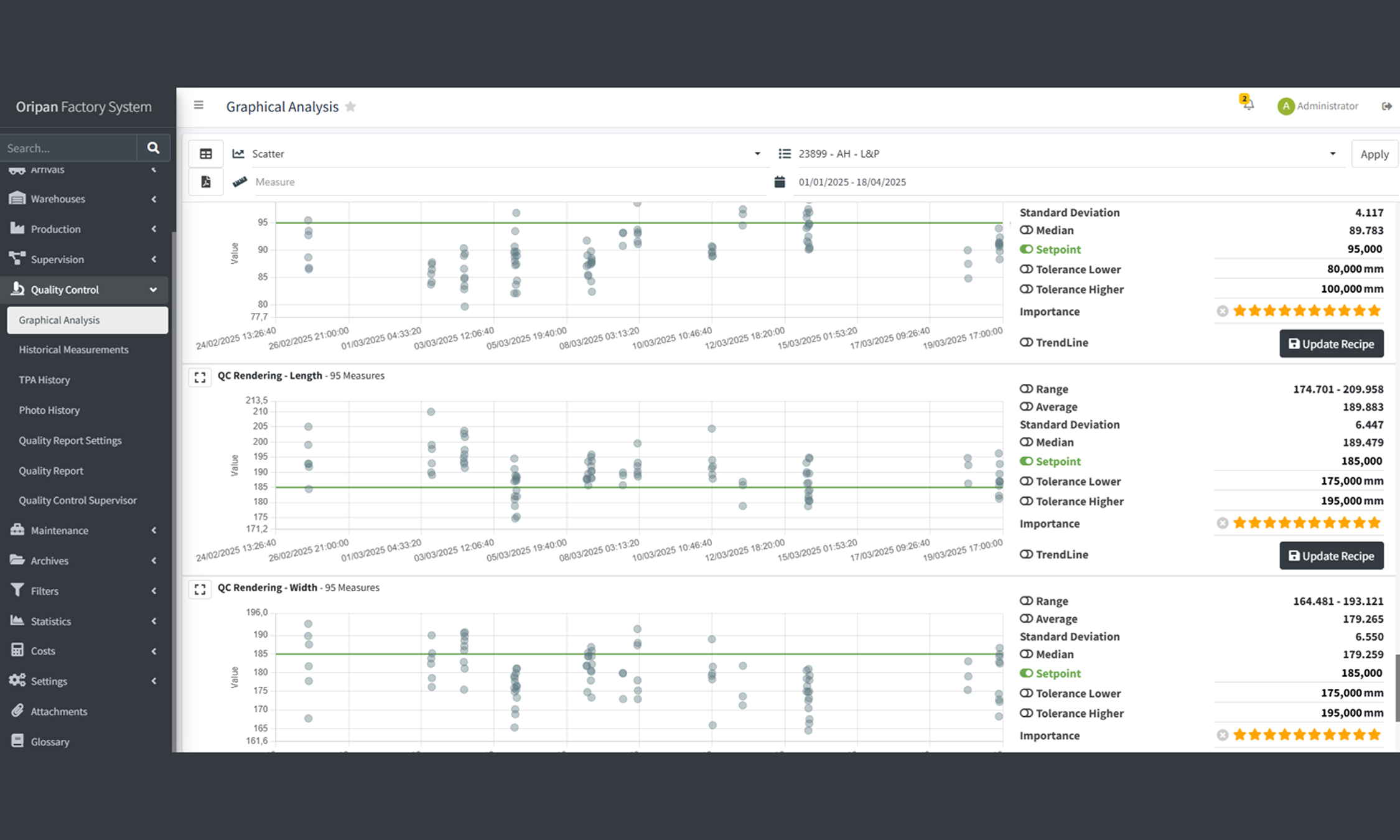

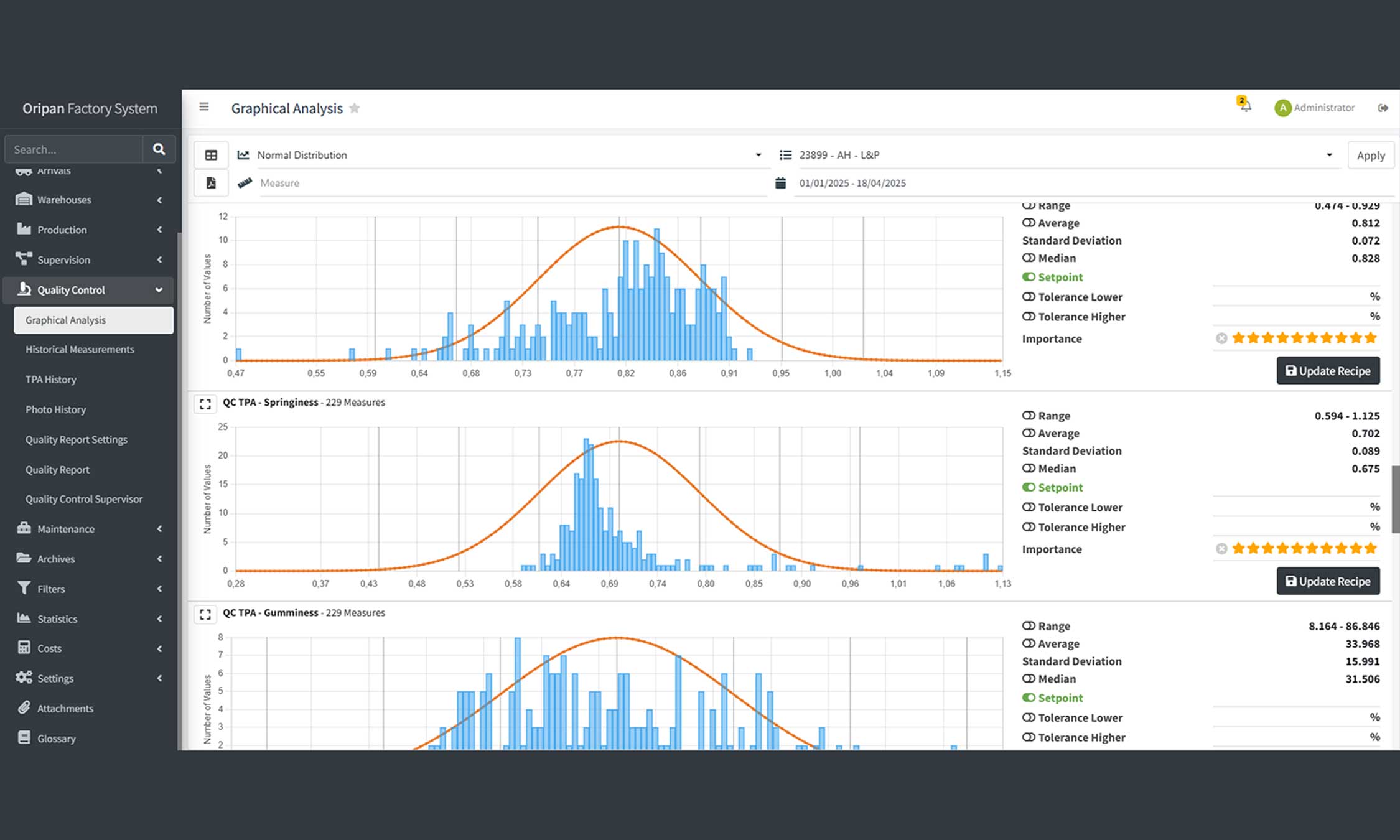

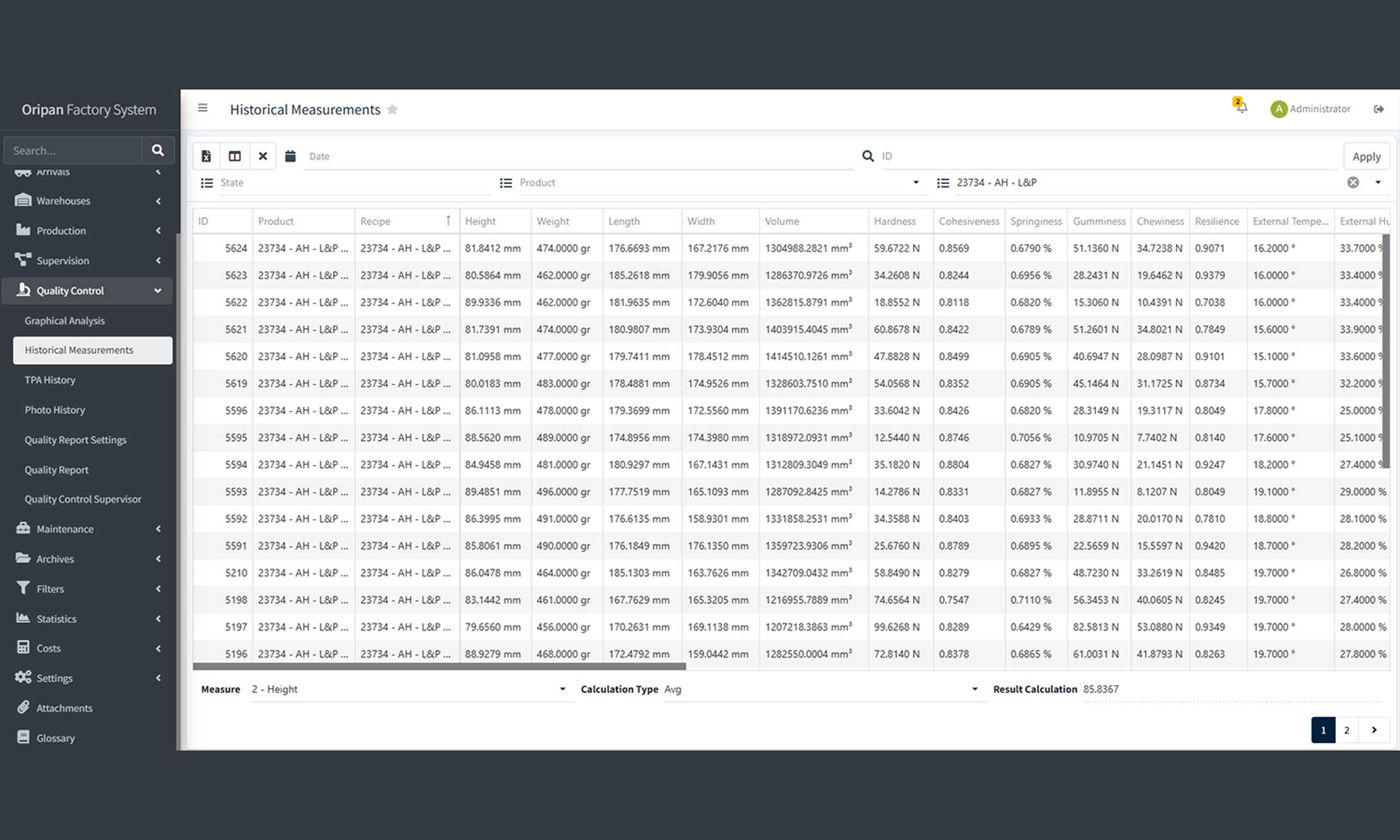

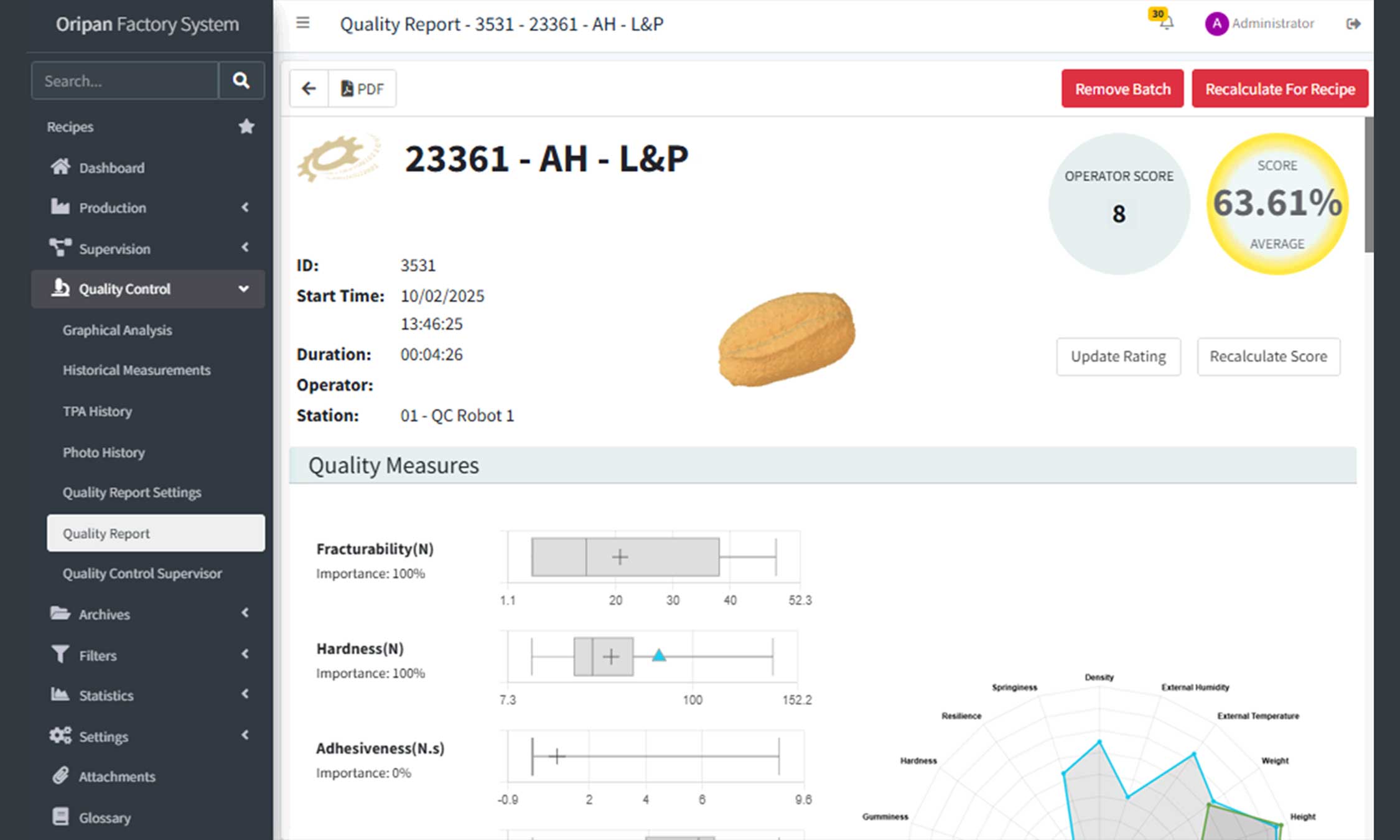

For each batch passing through the line, some samples are analyzed and the measurements of the products being tested are compared with the relevant standard in the recipe notifying any deviation.

By leveraging comprehensive production data within our OFS platform, OriQ enables in-depth analysis to identify the root causes of quality deviations —whether in upstream processes, raw materials, or machine settings— allowing timely interventions to restore the process to optimal specifications.