FOURNEO is an industrial bakery specializing in the production of high-quality flatbreads, including Pinsa Romana and Focaccia. Established in 2018, the company emphasizes traditional fermentation methods, allowing their dough to ferment for 72 hours to enhance both flavor and health benefits. FOURNEO’s commitment to quality and innovation positions them as a notable player in the industry.

Complete digitalization & control @FOURNEO

300 rue Gilbert Chiquet 62500 Leulinghem, France

300 rue Gilbert Chiquet 62500 Leulinghem, France

The Challenge

Fourneo embarked on the construction of a fully automated production facility. However, they faced the challenge of finding an integrated solution to seamlessly control and manage the entire factory. Given the long and articulated production process, real-time insights into product quality and production efficiency were at the utmost importance. Additionally, they required robust tracking of raw materials for traceability and certification purposes, as well as complete visibility into every aspect of their production operations including new equipment maintenance management. Without a centralized system, achieving these objectives would be complex and time-consuming, making it critical to find a solution that could deliver comprehensive oversight and efficiency.

The Solution

To address Fourneo’s challenges, we offered our complete OFS solution, a fully integrated system designed to digitalize, control, and integrate every stage of the production process. Our solution provides end-to-end visibility, starting from the arrival of raw materials to the delivery of the final product.

The offered solution in pills

- Warehouse & stock management (raw material arrivals, supplier contracts management, warehouse unloads, MRP..)

- Production planning

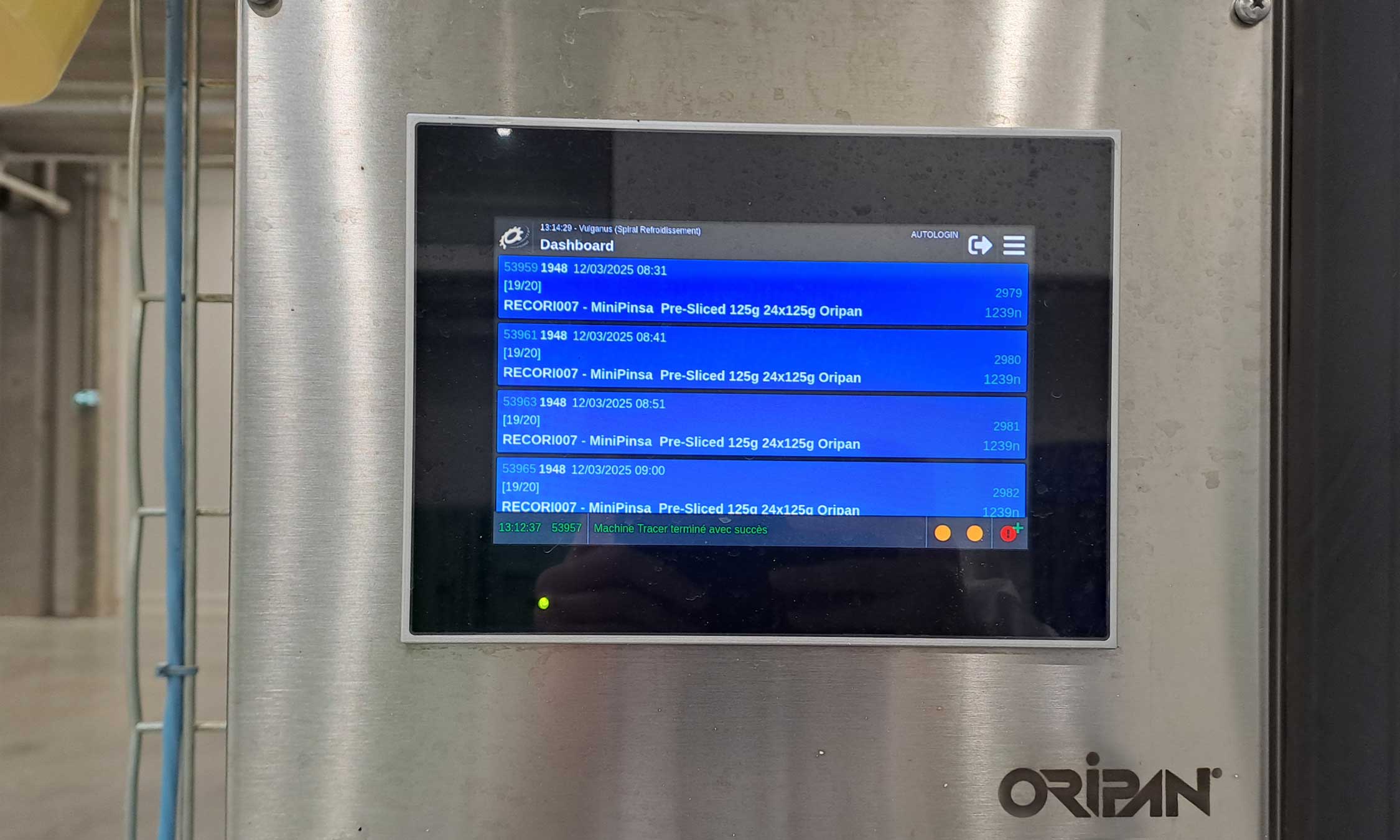

- Track & trace of raw materials and packaging materials

- Ingredients preparation

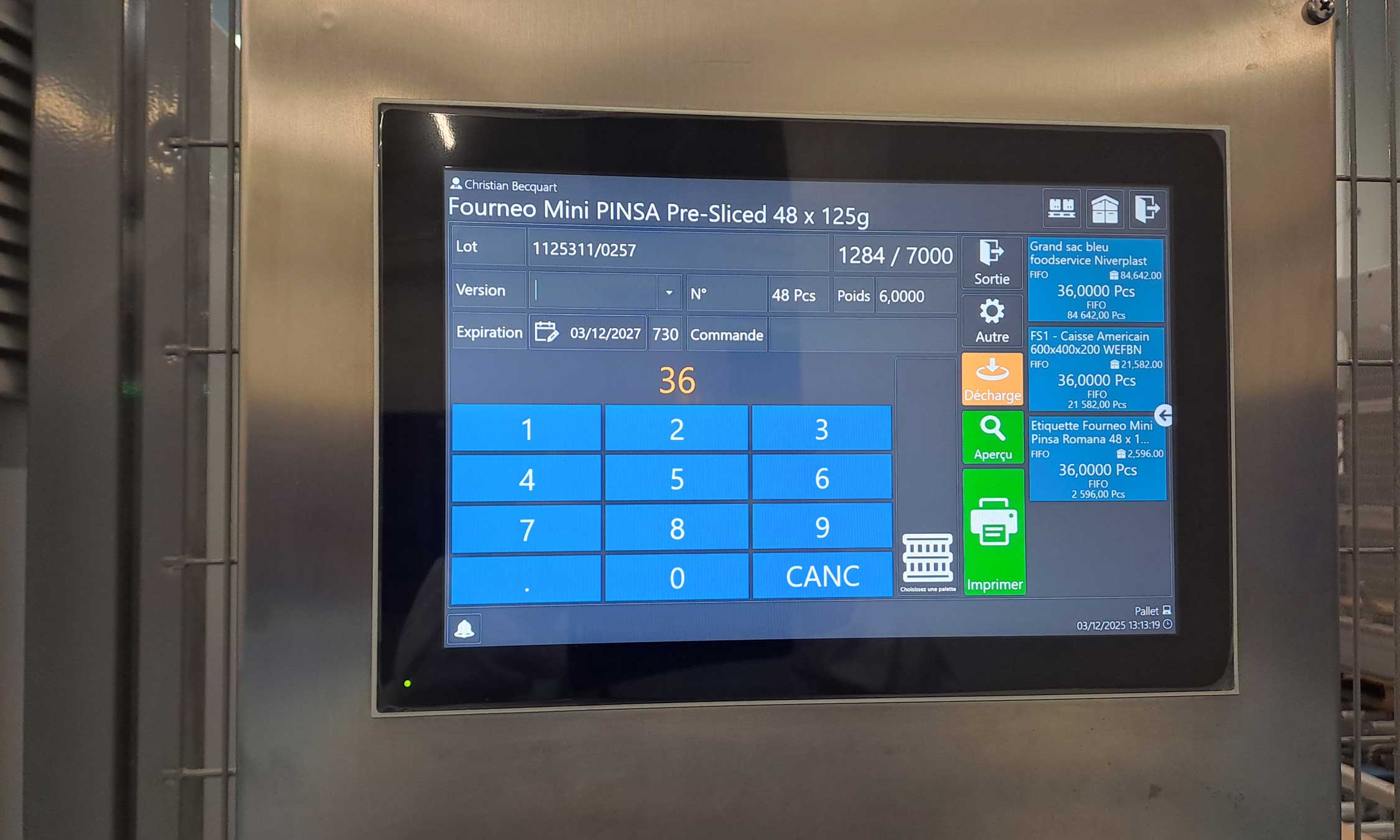

- Integration with all production machines to track batch in transit and collect/analyse production data

- Packaging management:

- Primary packaging: piece counter registration and load/tracking of packaging materials

- Secondary packaging: printing of pallets labels & final product warehouse load

- Customer orders picking & delivery management

- Final product datasheets, nutritional values, and allergens management

- Maintenance module for preventive and downtime management with maintenance tablets, spare parts stocks and inventory

- Cost analysis module for primary cost calculation

The impact

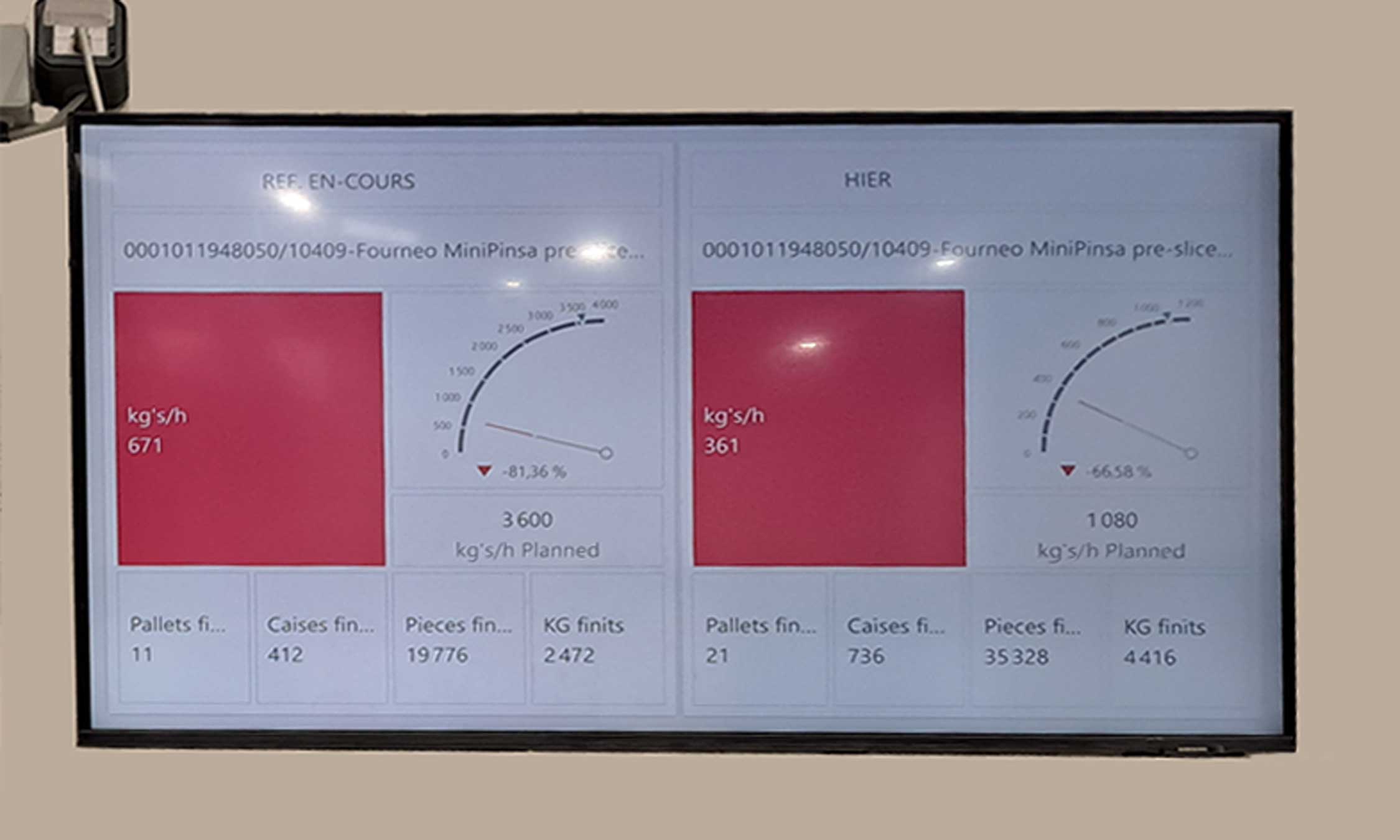

By integrating all aspects of production into a single platform, OFS empowered Fourneo with the tools and insights needed to optimize operations and achieve their ambitious goals.

- Reduced management time & costs

- Insights about production costs and efficiency

- Possibility to timely react to process deviations

- Full control of the production facility